Section II: Installation - Accessories

2.6.INS.ACC.11H99

INSTALLATION INSTRUCTIONS – CONTAINER VARIABILITY SYSTEM

1. Review all directions and diagrams provided before starting the CVS installation.

2. Attach the base plate bracket (

Pt. No. 23H76

) to the CVS sub-assembly (

Pt. No. 12H01

)

with fasteners provided (see

CVS Install Detail

on

Pg. 2

-

27

).

3. Position the CVS sub-assembly with attached base plate bracket on the side of the Main

Frame Z-Channel (see

Pg. 2-27

). Drill the necessary Ø13/32” holes into the Z-Channel

using the CVS sub-assembly with attached base plate bracket as the pattern to aid in

locating hole placement. To allow for CVS sub-assembly (

Pt. No. 12H01

) fastener clearance

some notching of the Z-Channel lip may be necessary.

4. Attach the CVS sub-assembly and base plate bracket to the Main Frame Z-Channel with

fasteners provided (see

Pg. 2-27

).

5. Drain hydraulic oil level in the tank to just below the 1 1/4” NPT Port.

6. Remove the 90-degree hydraulic fitting (

Pt. No. 10P44

) that connects the upper hydraulic

steel tubing to the top bulkhead fitting (see

Pg. 5-9

). Replace with a swivel tee hydraulic

fitting (

Pt. No. 11P85

) and retighten the hydraulic fittings (see

Pg. 2-28

).

7. Remove the 1 1/4" NPT plug from the hydraulic tank. Install hydraulic fittings

12P20 &

12P92

as shown and tighten (see

Pg. 2-28

).

8. Install the two 90-degree hydraulic fitting (

Pt. No. 12P69

) into the hydraulic valve on the

12H01

CVS sub-assembly and tighten (see

Pg. 2-28

).

9. Attach the hydraulic hose (

Pt. No. 12P87

) between the CVS hydraulic valve and swivel tee

hydraulic fitting (

Pt. No. 11P85

) and tighten (see

Pg. 2-28

).

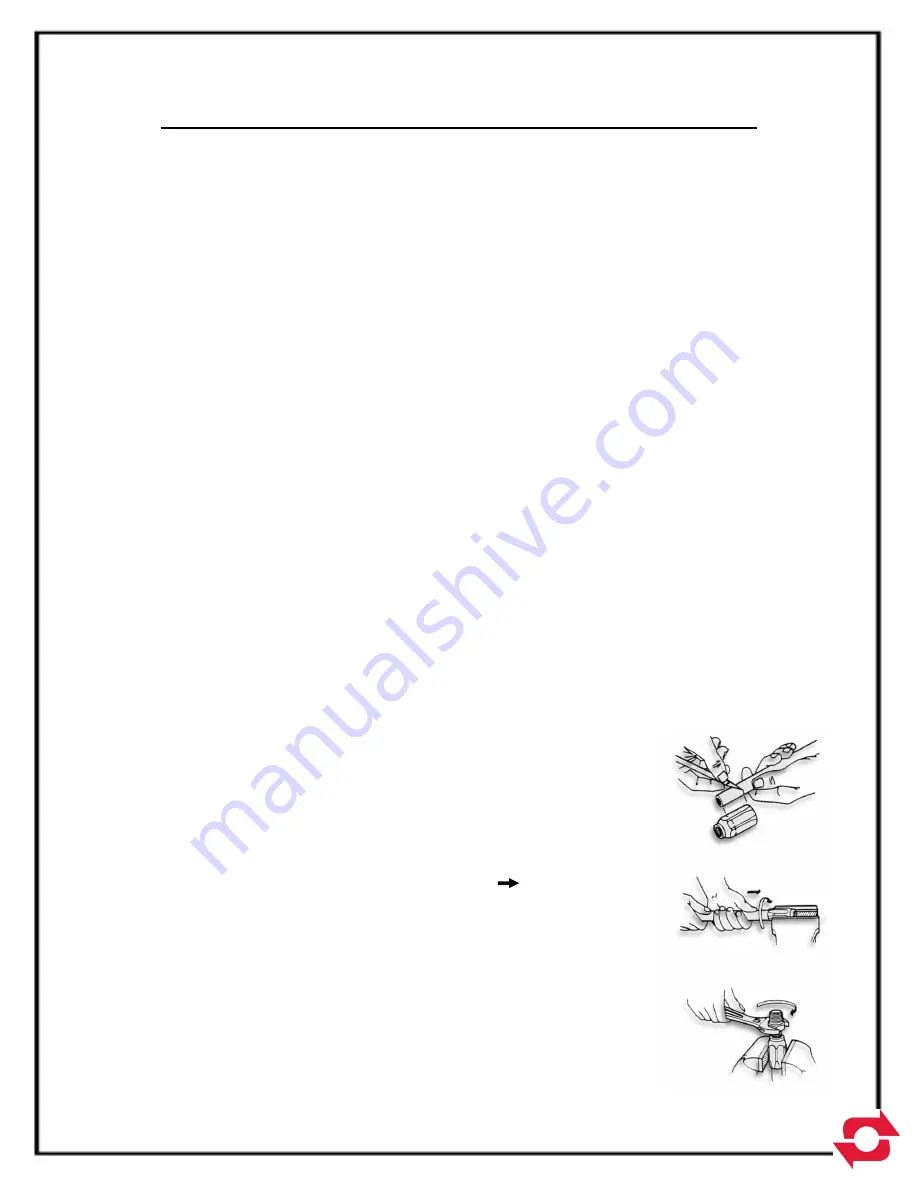

10. Determine the length of hose required to route the CVS hydraulic

valve to the hydraulic tank; the hydraulic hose (

Pt. No. 12P93

) may

need shortened prior to final installation (see

Pg. 2-28

) especially if

excess length exists. The hydraulic hose (

Pt. No. 12P93

) comes with

a reusable fitting that can be removed for purposes of shortening the

hose. Remove the reusable fitting and shorten hose assembly as

required. After hose has been shortened, lubricate the insert threads

of the fitting and the I.D. of the hose (see Illustration ). Measure

1 3/16” from the end of the hose and mark the hose for the socket

depth. Screw the hose into the socket (left-hand thread) to the depth

marked on the hose. Screw the insert into the socket until the insert

touches the socket. Clean the inside of the hose assembly by either

clean compressed air through it or by flushing it.

11. Once the overall hose length is adjusted, install between the CVS

hydraulic valve and the hydraulic tank fittings (see

Pg. 2-28

), and

tighten.

2-29

Содержание SL-214

Страница 1: ...Hooked on Quality PA R T S A N D O P E R AT I O N M A N U A L HOIST SERIAL NUMBER MODEL SL 214...

Страница 2: ......

Страница 30: ...This Page Intentionally Left Blank...

Страница 40: ...This Page Intentionally Left Blank...

Страница 46: ...This Page Intentionally Left Blank...

Страница 51: ...Section II Installation Accessories 2 8 INS ACC LEDLB 2 39...

Страница 52: ...This Page Intentionally Left Blank...

Страница 56: ...This Page Intentionally Left Blank...

Страница 64: ...This Page Intentionally Left Blank...

Страница 68: ...Section IV Maintenance 4 0 MAI SL 214 LUBRICATION DIAGRAM LEGEND GW Grease Weekly GM Grease Monthly 4 2...

Страница 78: ...This Page Intentionally Left Blank...

Страница 90: ...This Page Intentionally Left Blank...

Страница 105: ......

Страница 106: ...1800 NE BROADWAY AVENUE DES MOINES IA 50313 TOLL FREE 888 767 8000...