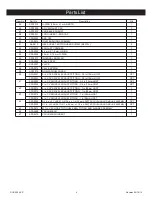

Symptom

Possible Cause

Solution

Low Power and/or Low Free Speed

Check air line pressure at the Inlet of

the Sander while the tool is running at

free speed. It must be 90 psig (6.2 Bar).

See the “Housing Disassembly” section

cleaning solution until all contaminates

and obstructions have been removed. If

(See the “Housing Assembly” Section).

Plugged Inlet Screen

Clean the Inlet Screen with a clean,

suitable cleaning solution. If Screen

does not come clean replace it.

One or more Worn or Broken Vanes

Install a complete set of new Vanes

(all vanes must be replaced for proper

operation). Coat all vanes with quality

pneumatic tool oil. See “Motor Disas-

sembly” and “Motor Assembly”.

Internal air leakage in the Motor Housing

indicated by higher than normal air con-

sumption and lower than normal speed.

Check for proper Motor alignment and

Lock Ring engagement. Check for

damaged O-Ring in Lock Ring groove.

Remove Motor Assembly and Re-Install

the Motor Assembly. See “Motor Disas-

sembly” and “Motor Assembly”.

Motor Parts Worn

Overhaul Motor. Contact authorized

SurfPrep

TM

Service Center.

Worn or broken Spindle Bearings

Replace the worn or broken Bear-

ings. See “Shaft Balancer and Spindle

Disassembly” and “Spindle Bearings,

AirSHIELD™ and Shaft Balancer As-

sembly”.

Air leakage through the Speed

Control and/or Valve Stem.

Dirty, broken or bent Valve Spring, Valve

or Valve Seat.

Disassemble, inspect and replace worn

or damaged parts. See Steps 2 and 3

in “Housing Disassembly” and Steps 2

and 3 in “Housing Assembly”.

Vibration/Rough Operation

Incorrect Pad

Only use Pad Sizes and Weights

designed for the machine.

Addition of interface pad or other material

Only use abrasive and/or interface

designed for the machine. Do not at-

tach anything to the Sanders Pad face

used with the Pad and Sander.

Improper lubrication or buildup of foreign

debris.

Disassemble the Sander and clean in

a suitable cleaning solution. Assemble

the Sander.

Worn or broken Rear or Front Motor

Bearing(s)

Replace the worn or broken Bearings.

See “Motor Disassembly” and “Motor

Assembly”.

For vacuum machines it is possible to

have too much vacuum while sanding on

the sanding surface.

For SGV machines add extra washer(s)

to the pad spindle to increase the gap

between the pad and shroud. For CV

machines reduce vacuum through

the vacuum system and/or add extra

washer(s) to the pad.

Troubleshooting Guide

DOC 0004-SP

12

Revision 06/18/14