58

| Optidrive P2 User Guide |

Version 3.07

www.invertekdrives.com

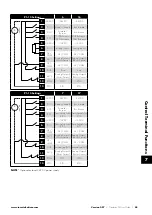

Par

Name

Minimum

Maximum

Default

Units

P5-07 Fieldbus Ramp Control

0

1

0

-

0

Disabled

Ramps are controlled from internal drive parameters P1-03 and P1-04.

1

Enabled

Ramps are controlled directly by the Fieldbus PDI4 Data Word.

P5-08 Fieldbus PDO-4 Data Select

0

7

0

-

0

Motor torque

0 to 2000 = 0 to 200.0%

1

Motor power

Output power in kW to two decimal places, e.g. 400 = 4.00kW

2

Digital Input Status

Bit 0 indicates digital input 1 status, bit 1 indicates digital input 2 status etc

3

Analog Input 2

0 to 1000 = 0 to 100.0%

4

Heatsink Temperature

0 to 100 = 0 to 100°C

5

User register 1

User Defined Register 1 Value

6

User register 2

User Defined Register 1 Value

7

P0-80 value

User Selected data value

P5-12

Fieldbus PDO-3 Data Select

0

7

0

-

0

Motor current

Output current to 1 decimal place, e.g. 100 = 10.0 Amps

1

Motor power

Output power in kW to two decimal places, e.g. 400 = 4.00kW

2

Digital input status

Bit 0 indicates digital input 1 status, bit 1 indicates digital input 2 status etc

3

Analog Input 2

0 to 1000 = 0 to 100.0%

4

Heatsink Temperature

0 to 100 = 0 to 100°C

5

User register 1

User Defined Register 1 Value

6

User register 2

User Defined Register 2 Value

7

P0-80 value

User Selected data value

P5-13

Fieldbus PDI-4 Function Select

0

1

0

-

0

Fieldbus ramps

This option must be selected if the drive acceleration and deceleration ramps are to

be controlled from the fieldbus. P5-07 must also be set to 1 to enable this function.

1

User register 4

The value received by the drive in PDI 4 is transferred to User Register 4. This option

allows the function of the process data word to be defined in Parameter Group 9.

In this case, User Register 4 should not be written to within any PLC function code,

although the value can be read.

P5-14

Fieldbus PDI-3 Function Select

0

2

0

-

0

Torque reference / limit

This option must be selected if the drive output torque limit / setpoint is to be controlled

from the fieldbus. This also requires setting P4-06 = 3.

1

PID reference

This option allows the setpoint to the PID controller to be received from the Fieldbus. In

order for this option to be used, P9-38 must be set to 1, and the PID User setpoint must

not be utilised within the PLC function.

2

User register 3

The value received by the drive in PDI 3 is transferred to User Register 3. This option

allows the function of the process data word to be defined in Parameter Group 9.

In this case, User Register 3 should not be written to within any PLC function code,

although the value can be read.

P5-15

Modbus Response Delay

0

16

0

Chr

Allows the user to configure an additional delay between the drive receiving a request via the Modbus RTU interface, and transmitting a

reply. The value entered represents the delay in addition to the minimum delay permissible according to the Modbus RTU specification,

and is expressed as the number of additional characters.

P5-16

Drive Modbus Address

0

273

0

-

The drive Modbus (and Optibus) address is set in P5-01 which has a maximum value of 63. If a higher Modbus address is required for a

larger network, it can be set in this parameter.

If this parameter is set to a value greater than 0, this address will become the Drive Modbus address. If this value is set to 0, P5-01

determines the Drive Modbus address.

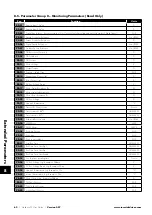

8.4. Advanced Parameters

For Advanced Parameters, basic information only is provided in this guide. The parameter functions are described more fully in

Optitools Studio PC software.

8.4.1. Parameter Group 6 – Advanced Configuration

8

Extended P

arameters