56

| Optidrive P2 User Guide |

Version 3.07

www.invertekdrives.com

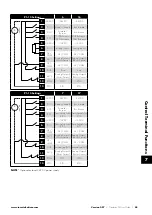

Par

Parameter Name

Minimum

Maximum

Default

Units

P4-08 Minimum Torque Limit

P4-08

150

0

%

Active only in Vector Speed or Vector Torque motor control modes (P4-01 = 0 or 1). Sets a minimum torque limit, whereby when the

Optidrive is enabled, it will always attempt to maintain this torque on the motor at all times whilst operating.

NOTE This parameter should be used with extreme care, as the drive output frequency will increase to

achieve the torque level, and may exceed the selected speed reference.

P4-09 Regenerative Torque Limit

0.0

500

100

%

Active only in Vector Speed or Vector Torque motor control modes (P4-01 = 0 or 1). Sets the maximum regenerating torque allowed by

the Optidrive.

P4-10

V/F Characteristic Adjustment Frequency

0.0

P1-09

0.0

Hz

When operating in V/F mode (P4-01 = 2), this parameter in conjunction with P4-11 sets a frequency point at which the voltage set in

P4-11 is applied to the motor. Care must be taken to avoid overheating and damaging the motor when using this feature.

P4-11

V/F Characteristic Adjustment Voltage

0

P1-07

0

V

Used in conjunction with parameter P4-10.

P4-12

Thermal Overload Retention

0

1

1

-

0

Disabled

1

Enabled

All Optidrives feature electronic thermal overload protection for the connected motor, designed to protect

the motor against damage. An internal overload accumulator monitors the motor output current over time,

and will trip the drive if the usage exceeds the thermal limit. When P4-12 is disabled, removing the power

supply from the drive and re-applying will reset the value of the accumulator. When P4-12 is enabled, the

value is retained during power off.

P4-13

Output Phase Sequence

0

1

0

-

0

U,V,W

Stand motor phase sequence. Typically, this provides clockwise rotation of the motor.

1

U,W,V

Reverse motor phase sequence. Typically this provides counter-clockwise rotation of the motor.

P4-14

Thermal Overload Reaction

0

1

0

-

0

Trip

When the overload accumulator reaches the limit, the drive will trip on It.trp to prevent damage to the motor.

1

Current

Limit

Reduction

When the overload accumulator reaches 90% of, the output current limit is internally reduced to 100%

of P1-08 in order to avoid an It.trp. The current limit will return to the setting in P4-07 when the overload

accumulator reaches 10%.

P4-15

Master Mode Configuration (Master-Slave Mode)

0

1

0

-

0

Motor speed

& torque

reference

In this mode, when the drive functions as a Master in Master-Slave Mode, the data broadcast on the drive

network is the Master Actual Speed and the Master Torque Reference. This mode is suitable for Master-

Slave applications which required speed following.

1

Speed

reference &

motor torque

In this mode, when the drive functions as a Master in Master-Slave Mode, the data broadcast on the drive

network is the Master Speed Reference and the Master Actual Torque. This mode is suitable for Master-

Slave applications which required load sharing between multiple drives.

8.3. Parameter Group 5 – Communication Parameters

8.3.1. Overview

Optidrive P2 provides many methods to allow the user to connect to a variety of fieldbus networks. In addition, connection to options

such as external keypads, PC and Optistick are possible. Parameter Group 5 provides the parameters required to configure the

various fieldbus interfaces and connection points.

8.3.2. Connecting Invertek Drives Options

All Invertek Drives options which require communication with the drive, such as the Optiport and Optipad remote keypads and

Optistick connect to the Optidrive P2 using the built in RJ45 connection point. The pin connections on these options are already

matched, such that a simple pin to pin plug in cable can be used to connect these options without any special requirements.

For further information on connecting and using these optional items, refer to the specific option User guide.

8

Extended P

arameters