16E / 16E-H / 16E-P Spray Gun

18

MAN 96150 EN 01

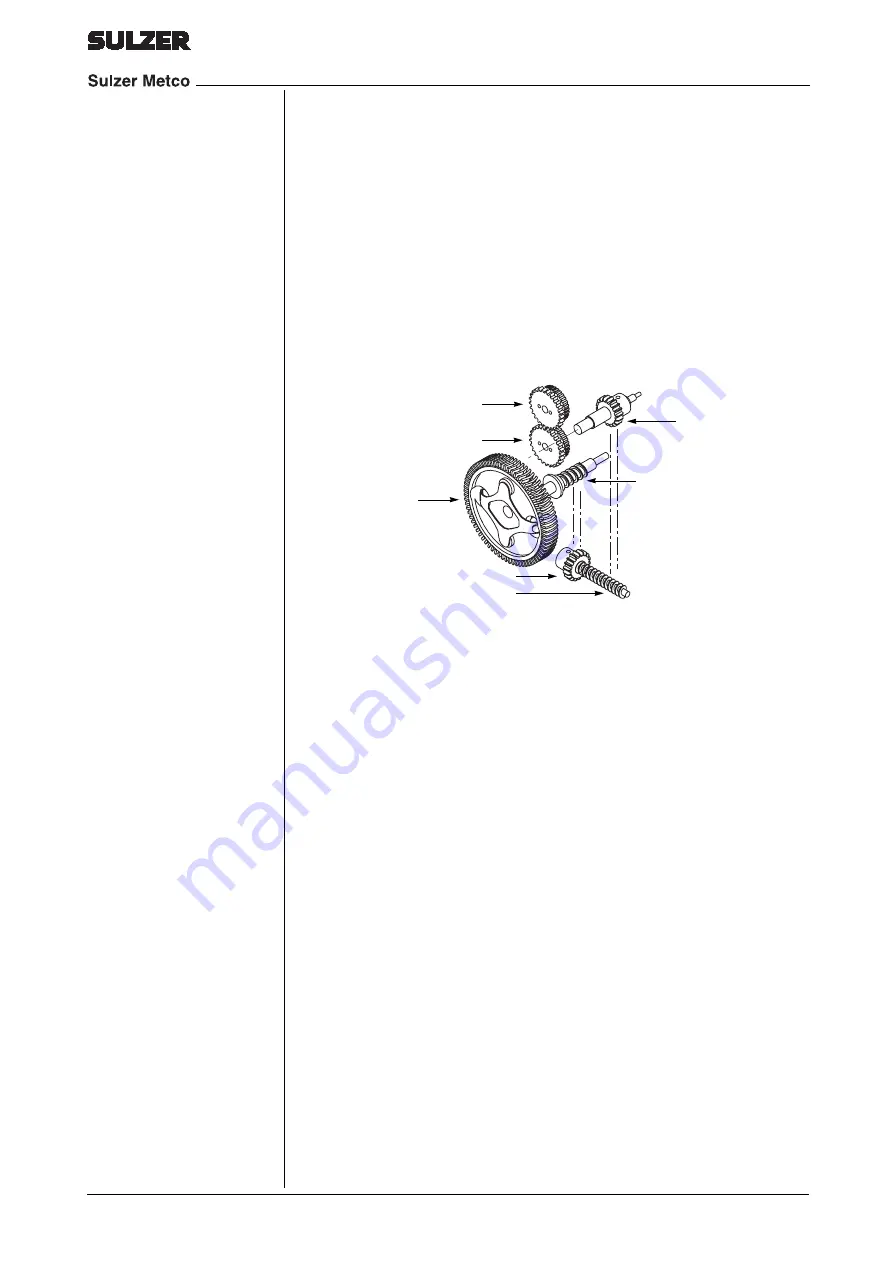

2.2.3 Turbine and Speed Control

The turbine is air-driven and spins at a high rate of speed whenever air

flow is present (i.e., gas head valve is in the run position). Turning the

control ring decreases or increases pressure on the brake plate which

allows the turbine to spin faster or slower, thus adjusting the wire feed

rate.

2.2.4 Countershaft and Bearing Assembly

The following illustration shows the mechanical relationship between

the countershaft, drive shaft, turbine shaft and drive roll gears.

The turbine shaft meshes with the countershaft gear. This results in a

reduction in turn ratio from the turbine shaft to the countershaft. The

countershaft meshes with the drive shaft gear, resulting in a further

reduction in turn ratio to the drive shaft and the lower drive roll and

gear. The upper drive gear engages the lower drive gear only when

wire is being fed. When the upper and lower drive gears engage, the

upper and lower drive rollers grip and feed the wire.

Although the air turbine is light-weight and spins at very high speed

(up to 30,000 RPM), the gear reduction results in a much lower speed

and a much higher torque at the drive shaft. The reduction ratio

through the shafts and gears is not important, except to note that the

16E-H (high-speed) gun has a different turbine shaft and countershaft

gear for higher range of feed rate. Additionally, the upper and lower

drive rolls and gears can be changed to accommodate different

gauges of wires. (See “Hardware Selection” on page 26.)

The countershaft and bearing covers are gasket-sealed to the central

housing and contain Gearlube oil. The oil is circulated through an oil

pump by the motion of the countershaft and drive shaft gear.

Upper Drive Roll / Gear

Lower Drive Roll / Gear

Turbine

Countershaft Gear

Countershaft

Turbine Shaft

Drive Shaft / Gear

16e_gearing