16

CoMPoNENT DESCRIPTIoN

3.1

PORTABLE COMPRESSOR PACKAGE

The compressor is a single stage, oil-flooded lubricated rotary screw air compressor. The compressor

package is available as a portable wheel-mounted unit, utility mounted unit, or galvanized skid-mounted

unit for offshore applications. All models are enclosed in a weather-resistant acoustical enclosure.

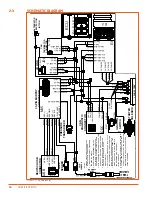

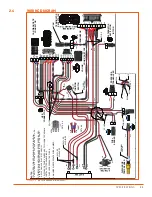

The complete operating unit consists of a diesel engine for power, compressor assembly, air/oil separator

system, cooling system for the engine and compressor oil, instrumentation, pneumatic control system, and

acoustical enclosure.

3.2

ENGINE

The compressor is powered by a diesel engine. For detailed information on the engine refer to the Engine

operators Manual provided with each compressor.

3.2.1

ENGINE COOLING SYSTEM

The engine cooling system utilizes a conventional engine radiator, thermostat, water pump, and fan to

maintain the engine coolant at a desired operating temperature.

3.2.2

ENGINE TO COMPRESSOR DRIVE

The compressor and engine are connected through a non-lubricated spline coupling. It consists of a drive

ring registered and bolted directly to the engine flywheel and either a splined hub or a disc attached to the

compressor drive shaft. because of low starting torque, no clutch is required.

3.3

AIR END ASSEMBLY

The compressor assembly is an oil flooded, positive displacement, single stage rotary screw unit.

Components include a stator housing, male and female rotors, bearings, and bearing supports. Engine power

is transferred to the male rotor through a coupling and, if a gear-driven unit, through gears in the gear

housing. The male rotor drives the female rotor.

3.3.1

COMPRESSION CYCLE

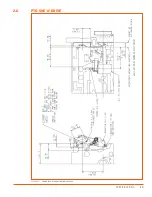

Figure 3-1.

COMPRESSION CyCLE

Air at atmospheric pressure is drawn in through the inlet and compressed by the rotation of the rotors.

During the compression cycle, oil is injected into the compressor performing three important functions:

1.

lubricate the rotating parts and bearings.

2.

Provide cooling for the compressed air.

3.

Seal the running clearances between the rotors.

3.4

DISCHARGE SYSTEM

3.4.1

reCeiVer/SuMP

From the compressor discharge, oil-laden air enters the receiver/sump tank above the oil level and most

of the oil is separated from the air by gravity. The oil runs downward and accumulates for recirculation,

while the remaining oil mist passes through the separator element. The oil separator is located in the upper

portion of the receiver/sump. When air is demanded at the service line, it passes through the separator

element, which provides the final stages of air/oil separation.

3.4.2

MINIMUM PRESSURE VALVE

A minimum pressure valve is provided at the service air outlet (at the top of the separator). This valve

serves to maintain a minimum discharge pressure of 65 to 80 psig in operation, which is required to assure

proper air/oil separation. At normal operating pressure of 90 to 150 psig, this valve is wide open, effectively

removing any restriction to airflow.

Содержание D260UJD4PTOW

Страница 4: ......

Страница 6: ...vi About This Manual ...

Страница 14: ...6 Safety ...

Страница 21: ...13 Specifications 2 6 PTO SAE A DRIVE Figure 2 5 Power Take Off Auxiliary Drive Specs ...

Страница 22: ...14 Specifications ...

Страница 32: ...24 Component Description ...

Страница 44: ...36 Installation and Operation ...

Страница 58: ...50 Troubleshooting ...

Страница 125: ...117 Parts Catalog ...

Страница 134: ...NOTES ...

Страница 135: ...NOTES ...