Maintenance

5

Maintenance safety instructions

• Check the vertical creep of the truck.

• Check the smooth movement of the wheels.

• Check the function of the emergency brake

by activating the emergency button.

• Check, the tiller arm- switch braking func-

tion

• Check the lifting and lowering functions by

operating the buttons.

• Check if all bolts and nuts are tightened

firmly.

• Visual check if there are any broken hoses

or broken electric wires.

Servicing and maintenance personnel training and qualification

Truck maintenance must only be carried out

by qualified and authorised personnel.

The annual inspection for prevention of

accidents at work must be carried out by a

person qualified to do so. The person carrying

out this inspection must provide their expertise

and opinion without being influenced by

economic factors or company internal issues.

Safety is the only critical deciding factor.

The person responsible for carrying out the

inspection must have sufficient knowledge

and experience to be able to assess the

condition of the truck and the efficiency of

the protective installations in accordance

with the technical regulations and principles

established for checking industrial trucks.

Battery maintenance staff

Batteries must only be recharged, maintained

and changed by specially trained personnel.

Personnel must follow the manufacturer’s

instructions of the battery, the battery charger

and the truck.

It is essential to follow the battery maintenance

instructions and the battery charger operating

instructions.

Maintenance operations that do not require special training

Simple maintenance operations such as

checking the hydraulic fluid level or checking

the battery electrolyte level can be carried out

by persons with no special training.

A specific qualification is not necessary.

Complicated maintenance operations such

as replacing the battery, replacing the wheels

and so on should be carried out by the autho-

rised service centre.

Refer to the maintenance section of this

manual for further information.

Maintenance safety instructions

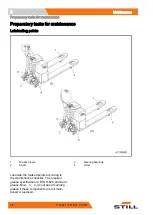

List of inspections

Maintenance checklist

Interval

Monthly

6 Month

12 Month

1133 801 16 01 EN - 11/2018

55

Содержание ECU 15C

Страница 1: ...Original instructions Electric pallet truck ECU 15C 0138 1133 801 16 01 EN 11 2018 ...

Страница 2: ......

Страница 8: ......

Страница 9: ...1 Introduction ...

Страница 23: ...Introduction 1 Residual risks 1133 801 16 01 EN 11 2018 15 ...

Страница 28: ...1 Introduction Residual risks 20 1133 801 16 01 EN 11 2018 ...

Страница 29: ...2 Safety ...

Страница 41: ...3 General views ...

Страница 45: ...4 Operation ...

Страница 61: ...5 Maintenance ...

Страница 70: ...5 Maintenance Trouble shooting 62 1133 801 16 01 EN 11 2018 ...

Страница 71: ...6 Technical data ...

Страница 77: ......

Страница 78: ...STILL GmbH 1133 801 16 01 EN 11 2018 ...