st

eut

e T

echnol

ogies GmbH & Co. K

G

Brück

ens

tr

aße 91, 32584 Löhne, Germany

, www

.s

teut

e.c

om

3 / 16

//

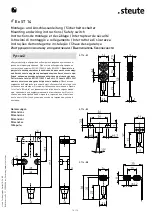

Ex ST 14

Montage- und Anschlussanleitung / Sicherheitsschalter

Mounting and wiring instructions / Safety switch

Instructions de montage et de câblage / Interrupteur de sécurité

Istruzioni di montaggio e collegamento / Interruttore di sicurezza

Instruções de montagem e instalação / Chave de segurança

Инструкция по монтажу и подключению / Выключатель безопасности

English

Maintenance, service, repair

=

DANGER

Live parts. Explosive atmosphere.

Electric shock

hazard! Explosion hazard! Risk of burns!

Do not

repair defective or damaged devices. Replace them.

Do not rebuild or modify the device in any way.

With careful mounting as described above, only minor maintenance is

necessary. We recommend a regular maintenance as follows:

1. Check switching function

2. Check for tight installation of the device and coded actuator.

3. Remove all dirt.

Disposal

- Observe national, local and legal regulations concerning disposal.

- Recycle each material separately.

N.B.

Do not use the device as a mechanical endstop. Any mounting position

is possible. Furthermore, EN 60079-14 has to be applied for the instal-

lation of electrical equipment in explosive areas. Moreover, the ATEX

test certificate and the special conditions therein have to be observed.

The device has been developed in order to assure safety functions as a

part of an entire plant or machine. A complete safety system normally

covers sensors, monitoring modules, indicator switches and concepts

for safe disconnection. For the integration of the device in the entire

system: strictly observe and respect the control category determined

in the risk assessment. Therefore, a validation according to EN ISO

13849-2 or EN 62061 is necessary.

Furthermore, the Performance

Level according to EN ISO 13849-1 and SIL CL Level according to EN

62061 can be lower than the single level because of the combination

of several safety components and other safety-related devices, e.g.

by serial connection of sensors.

It is the responsibility of the manufac-

turer of a plant or machine to guarantee the correct general function.

Subject to technical modifications. steute does not assume any liability

for recommendations made or implied by this description. New claims

for guarantee, warranty or liability cannot be derived from this docu-

ment beyond the general terms and conditions of delivery.

Français

Utilisation des instructions de montage et de câblage

Groupe cible: personnel autorisé et compétent.

Toutes les manipulations décrites dans cette notice d‘installation ne

doivent être effectuées que par du personnel formé et autorisé par la

société exploitante.

1. Lire et comprendre les instructions de montage et de câblage.

2. Respecter les règles de sécurité et de prévention des accidents

en vigueur.

3. Installer l’appareil et le mettre en service.

La sélection et l'installation des appareils et leurs intégrations dans

les systèmes de commande exigent une connaissance approfondie

in safety circuits to monitor the position of mobile safety guards to EN

ISO 14119 (EN 1088) type 2 and EN 60947-5-1.

Special conditions and »X« marking

- Position the device protected from shock loads.

- The device's connection cables must have a fixed installation and be

set up in a manner that protects them from mechanical damages.

- If the connection is in an explosive area, the connection cable has to

be connected in an enclosure which complies with the requirements

of an approved ignition protection degree according to EN 60079-0,

par. 1.

Installation, mounting, dismantling

=

DANGER

Live parts and explosive atmosphere.

Electric

shock hazard! Explosion hazard!

Before commis-

sioning, check device for correct installation. Com-

ply with national regulations.

=

DANGER

Live parts. Explosive atmosphere.

Electric shock

hazard! Risk of burns!

Connecting and disconnect-

ing only to be performed by qualified and author-

ised personnel. Connecting and disconnecting only

in non-explosive environment.

Mount the device and actuator on an even surface. Due to the danger

of manipulation: Prevent accessibility to actuators and spare actua-

tors. Ensure that the device cannot be moved from its position. Ensure

this in case of failure, too. For protection against manipulation use

one-way safety screws. These are optionally available. With other fas-

tening, e.g. riveting or welding, ensure that the immersion depth of the

coded actuating bracket does not change.

When mounting the actua-

tor and device, observe the requirements of EN ISO 14119, especially

paragraphs 5.1 to 5.4!

Observe the instructions in the standards

EN ISO 12100 and EN ISO 14120.

Application and operation

- Use device only within the permitted electrical load limits (see

technical data).

- For short-circuit protection, use fuse size 6 A (gG/gN).

- Use device only within the permitted ambient temperature range

(see product label and technical data).

Cleaning

- Use a damp cloth to clean devices in explosive areas. This prevents

electrostatic charge.

- In case of damp cleaning: Use water or mild, non-scratching,

non-chafing cleaners.

- Do not use aggressive cleaners or solvents.