5

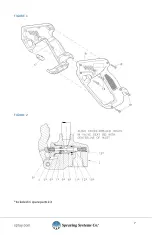

INSTALLATION

There is no need to remove the cover from the body unless the coil is changed,

or the interior requires cleaning. To ensure that the internal liquid and air

connections to the fluid module are maintained leak-free, the following

procedures should be observed:

1.

ALL FLUID PRESSURE MUST BE BLED OFF

when replacing the fluid

module, or the internal connection will leak.

2.

THE FLUID MODULE SHOULD BE REMOVED FIRST AND REPLACED

LAST

if servicing requires the cover to he removed. This allows the

cover to be completely tightened during assembly and easily loosened

during disassembly.

3.

If the cover is removed for any reason,

BE SURE COIL PROJECTIONS

ARE SEATED IN THE BODY HOLES SO THAT THE COVER CAN BE

COMPLETELY TIGHTENED

. Also, insure that the O-rings at each end of

the coil remain intact.

4.

THE COVER MUST BE FULLY TIGHTENED AGAINST THE BODY

since the

cover retains the fluid module in place and creates a seal for the air

and liquid connections. A loose cover will not allow the proper seals to

be made. Tighten cover by hand; wrenching is not required.

5.

FLUID MODULE MUST BE WRENCH TIGHTENED TO INSURE A SEAL

.

MAINTENANCE

With proper care, your CW1500A- Series GunJet

®

will give you reliable service.

To maintain this performance, parts should be inspected regularly and replaced

when necessary with genuine

Spraying Systems Co.

®

parts.

DISASSEMBLY PROCEDURE:

If it becomes necessary to rebuild the Valve Assembly (3 - 13) order Spare Parts

Kit ABCW1500A-KIT or ABCW1500AW-KIT, follow these steps:

1.

Make sure all air, electrical and liquid lines to the pump are turned off.

2.

Release all the pressure and liquid (from the hose to GunJet) by

operating Trigger until fluid ceases to flow

3.

Remove spray gun from hose