U s e r I n s t r u c t i o n s - E n g l i s h

10

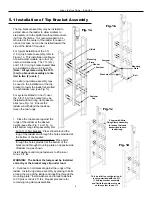

5.2 Installation of Cable to Top Bracket Assembly

Use only Miller approved cable.

Inspect cable before installation. Do not install damaged cable. Safety

glasses and gloves should be worn when handling cable.

When cutting the cable on site during the installation procedure is preferred or necessary, refer to 5.6 Options for

Terminating Cable in the Field.

WARNING: All instructions and warnings provided with the cable

termination fittings must be read and understood before using the equipment.

1. Install quick link to cable thimble (see Fig. 2).

2. Then connect quick link with cable to the shackle

on the underside of the inline shock absorber.

Tighten quick link until snug. Do not use if quick

link does not close and tighten.

NOTE: Ensure the cotter pin is through the

shackle bolt and bent over so that it will not back

out. DO NOT USE SYSTEM IF COTTER PIN IS

MISSING.

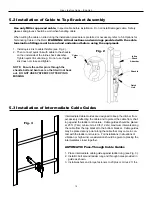

5.3 Installation of Intermediate Cable Guides

Intermediate Cable Guides are designed to keep the climber from

excessively deflecting the cable and to protect the cable from chaf

-

ing against the ladder or structure. Cable guides should be placed

at 25 ft. (7.6m) minimum to 40 ft. (12.2m) maximum intervals

along

the cable from the top bracket to the bottom bracket. Cable guides

may be placed at any point along the cable that may come in con-

tact with the ladder or structure. For installations in situations of

vibration or high wind, consideration should be given to placing the

intermediates closer together.

AUTOMATIC Pass-Through Cable Guides

1. Place intermediate cable guide against ladder rung (see Fig. 3).

2. Install U-bolt around ladder rung and through holes provided in

guide as shown.

3. Install washers and torque fasteners to 20 plus or minus 2 ft. lbs.

Fig. 3

Inline

Shock

Absorber

Shackle

Quick

Link

Cotter

Pin

Fig. 2

Содержание MILLER Vi-Go

Страница 1: ......