www.soundskulptor.com

Document revision 1.3 – Last modification : 28/02/20

MP 566 Assembly guide

Safety warning

This kit use high voltages that are potentially lethal. Under no circumstance should someone undertake the realisation of

this kit unless he has full knowledge about safely handling high voltage powered devices.

Please read the “DIY guide” before beginning.

Print or open the following documents :

•

MP566 Schematics

•

MP566 Components layout

•

MP566 Parts list

•

MP566 Test guide

Follow this guide from item number 1 till the end, in this order. The assembly order is based on components height, from

low to high profile, in order to ease the soldering process : The component you are soldering is always taller than the

previously assembled ones and it is pressing nicely against the work area foam.

Soldering

All the PCB holes are metallized. It means the connection between the top and bottom pads is already

done. The parts must be soldered only from below (unless differently stated).

Use only small diameter solder, 0.5 or 0.7 mm, 1mm maximum. Use the minimum possible amount of

solder. Bad joints are almost always caused by too much solder.

Warning

: Some components on this board carry high voltages. It is compulsory to cut the component

leads and pins totally flush with the PCB after soldering. A too long tail could create an electric arc with

the side plate.

Here are two excellent introduction to soldering videos:

http://www.eevblog.com/2011/06/19/eevblog-180-soldering-tutorial-part-1-tools/

http://www.eevblog.com/2011/07/02/eevblog-183-soldering-tutorial-part-2/

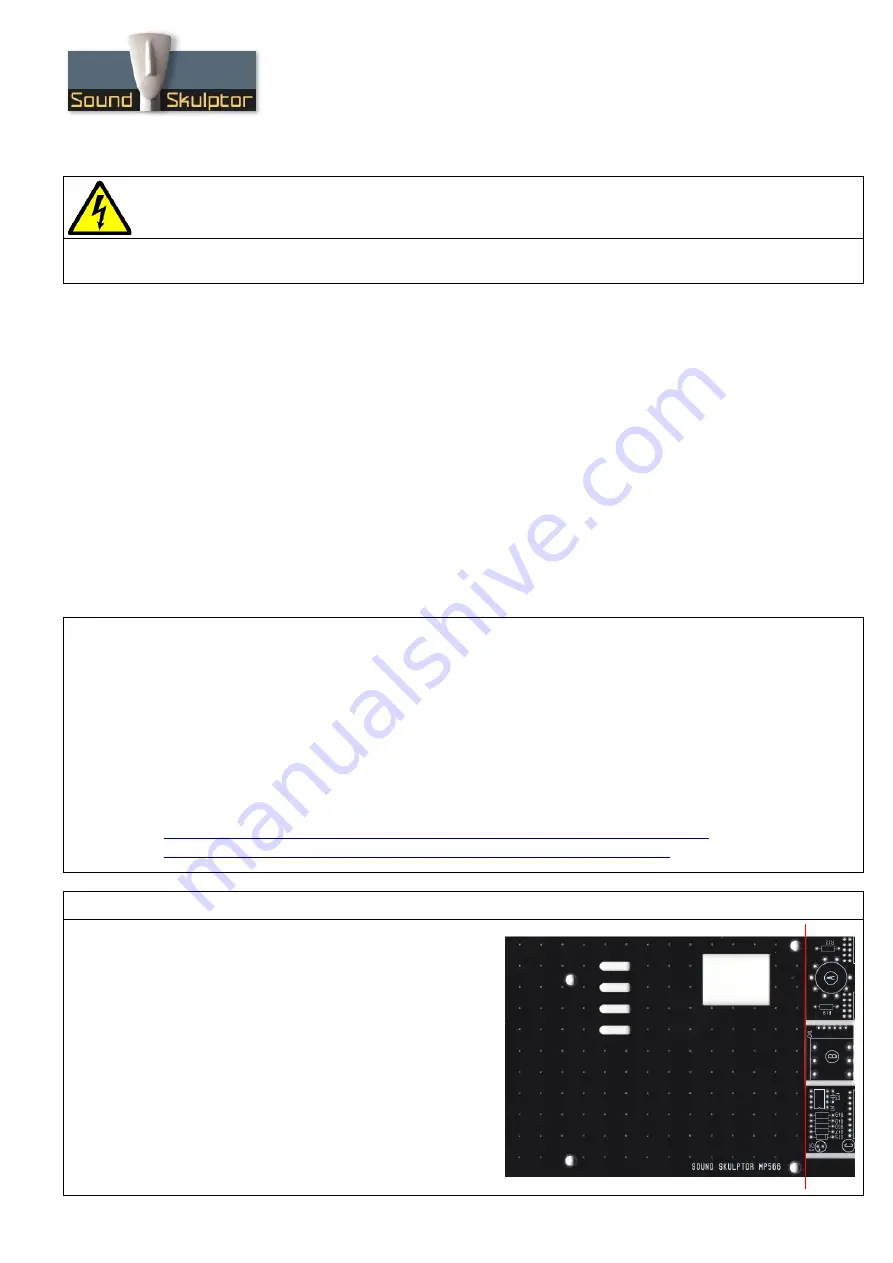

MP 566 Assembly guide – PCB split

1. PCB split

Split the multiple PCB along the red line on the

picture.

This will separate the tube PCB, the DI jack PCB,

the power-up PCB and the protection cover.

Clean up the break line with very thin sand paper.

Copyright ©2015 SoundSkulptor