SERVICE NOTE

SPECIFICATIONS

REPAIR PARTS LIST

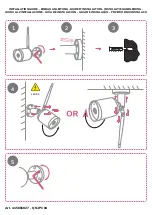

DISASSEMBLY

ADJUSTMENTS

SERVICE MANUAL

Link

Link

Revision History

Revision History

How to use

Acrobat Reader

How to use

Acrobat Reader

Sony EMCS Co.

SAL1870 (3.5-5.6/18-70) (DT 18-70mm F3.5-5.6)

Ver. 1.5 2008.04

LENS FOR DSLR CAMERA

2008D0800-1

© 2008.04

Published by Kohda TEC

9-876-947-13

US Model

Canadian Model

AEP Model

Chinese Model

SAL1870

(3.5-5.6/18-70) (DT 18-70mm F3.5-5.6)

• About the Lens Test Projector

Revised-2

Replace the previously issued

SERVICE MANUAL 9-876-947-12

with this Manual.