– 10 –

Button

Button Number or Display

CLEAR

3

CHECK

4

±

(AMS)

5

≠

(AMS)

6

PUSH ENTER

7

§

(OPEN/CLOSE)

9

INPUT

10

MEMO SEARCH

11

I/

u

18

TIME/TEXT

19

GROUP FILE

20

GROUP 8

21

GROUP 7

22

GROUP 6

23

GROUP 5

24

REPEAT

27

PROGRAM

28

SHUFFLE

29

CONTINUE

30

GROUP 4

31

GROUP 3

32

GROUP 2

33

GROUP 1

34

·

All lit (LED lit)

P

Partial lighting 1 (LED lit)

p

Partial lighting 2

DISC/

Partial lighting 3

CHARACTER

• When the jog dial is rotated to the right, the

GROUP LEDs light up in the order of 1

→

2..8

→

2nd

→

1.

• When the jog dial is rotated to the left, the

GROUP LEDs light up in the order of 8

→

7..1

→

2nd

→

8.

SECTION 4

TEST MODE

DISPLAY CHECK MODE

With the power turned off (standby state), press the

I/

u

button

while pressing the

P

(pause) button.

All FL segments and grids light up together with the

·

(play),

P

(pause), and standby LEDs.

At the same time, the GROUP LEDs are scanned one by one.

Note:

To exit this mode, press the

p

(stop) button.

ADJ MODE

1. Turn ON the power of the unit, set disc to disc table, and per-

form chucking.

2. Disconnect the power supply plug from the outlet.

3. To set ADJ mode, connect the test point (TP: ADJ) of the MAIN

board to Ground, and connect the power supply plug to the

outlet.

The power will turn on automatically, and the first track will be

played.

In this mode, table rotation and loading operations are not per-

formed because it is taken that the disc has already been chucked.

Note:

The same operations are also performed in the following when the

test point (TP: ADJ) is connected to Ground after turning on the

power.

• Direct search (movement of sledding motor) is not performed

during accessing

• Ignored even when GFS becomes L

• Ignored even when the Q data cannot be read

• Focus gain does not decrease

• Spindle gain does not decrease

• Servo related settings can be set manually and checked (Refer

to ADJ Mode Special Functions Table)

ADJ Mode Special Functions Table

(The buttons shown with ( ) function by using the sup-

plied remote commander only)

KEY AND FLUORESCENT DISPLAY TUBE CHECK

MODE

1. Connect the test point (TP:AFADJ) of the MAIN board to the

Ground, and insert the power plug to the outlet to set this mode.

First, the external SRAM is checked, and if abnormal, “SRAM

NG” is displayed.

If OK, the following steps are performed.

* Fluorescent Display Tube Check Mode

The whole fluorescent display tube lights up when the con-

nection in step 1 is made.

* Key Check Mode

This mode is set when a button is pressed after the whole

fluorescent display tube lights.

All buttons have a button number.

When a button is pressed, the counter display is counted up,

and the number of that button is displayed.

However, the counter display will only count up to 26, but

the number of buttons pressed will always be displayed.

**

**

O

Counter display

Button number display

Buttons and Corresponding Button Numbers

Button

Button Number or Display

CONTINUE

Servo average display

Displays VC, FE, RF, TE and traverse in hexadecimal

numbers

SHUFFLE

Focus bias display

Each time this is pressed, the focus bias is switched

between 1 and 2

1

Bias actually set

Optimum bias

Minimum jitter

2

U:Upper aliasing bias

L:Lower aliasing bias

PROGRAM

Auto gain display

Displays focus, tracking, sledding in hexadecimal

numbers

GROUP 1 (1)

Increases the focus bias in 8 steps.

GROUP 2 (2)

Sets the focus bias in the middle of aliasing.

GROUP 3 (3)

Turns off the tracking and sledding servo

GROUP 4 (4)

Returns the auto gain to the initial value (30)

GROUP 5 (5)

Turns off the focus servo

GROUP 6 (6)

Decreases the focus bias in 8 steps.

GROUP 7 (7)

Re-adjusts the focus bias

GROUP 8 (8)

Turns on the tracking and sledding servo

(9)

Switches the focus servo gain between normal and down

FG. norm: normal, FG. down: down

(10/0)

Sets the focus bias to 0 (no bias)

Next, displays the jitter measured at the focus bias set

CHECK

S-curve observation mode

CLEAR

Automatic eccentric measurement

The results of measurement is displayed in mm directly.

Содержание CDP-CX220 - 200 Disc Cd Changer

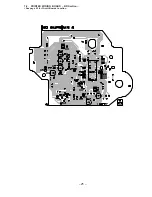

Страница 25: ... 25 7 2 PRINTED WIRING BOARD BD Section See page 22 for Circuit Boards Location ...

Страница 26: ... 26 Page 30 ...

Страница 30: ...CDP CX220 7 6 PRINTED WIRING BOARDS JACK Section See page 22 for Circuit Boards Location 33 34 Page 29 Page 30 ...

Страница 32: ...7 8 PRINTED WIRING BOARDS PANEL Section See page 22 for Circuit Boards Location 37 Page 38 Page 38 Page 29 ...

Страница 36: ... 42 Page 29 ...

Страница 37: ... 43 7 11 SCHEMATIC DIAGRAM SENSOR MOTOR Section CDP CX220 Page 31 Page 31 Page 31 Page 31 Page 31 ...