■

Battery Fluid Level

Batteries emit hydrogen and oxygen,

elements that can combine explosively.

DO NOT smoke or permit open flames or

sparks when checking batteries.

Figure 9.6 - Battery Fluid Level

Remove the caps from the battery and visually

check to see that the battery fluid is 1/4” (6 mm)

below the bottom of the filler neck inside each hole.

■

Hydraulic Oil Level

To check the hy drau lic oil level:

Com pletely lower the booms and en sure the sta bi -

lis ers are in the stowed po si tion.

Figure 9.7 - Hydraulic Oil Level

The hy drau lic oil level should be be tween the two

marks on the dipstick.

If nec es sary, add hy drau lic oil at the filler cap. See

the “Spec i fi ca tions” chap ter 4, for type and grade of

hy drau lic oil.

■

Hydraulic Oil Leaks

Leaking hydraulic oil can cause burns, fires,

falls (slipping), cuts, and puncture wounds

(if under high pressure).Do not search for

leaks with your hand. Have a qualified

trained maintenance person repair all

hydraulic fluid leaks before you operate an

EPV16.

Hy drau lic oil leaks are eas ily vis i ble and can show

up any place.

Vi sually in spect the en tire ma chine for hy drau lic oil.

Check the ground un der the ma chine for leaked oil.

Care fully in spect the ends of the up per and lower

booms. Oil can run down in side of the booms and

drip out the end.

In

spect all fit

tings and hoses for leaks. In

spect

hoses for signs of dam age from chaff ing or rub bing

against pro tru sions on the chas sis.

■

Bolts and Fasteners

Vi sually in spect all fas ten ers to see that none is

miss ing or ob vi ously loose.

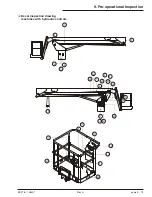

Figure 9.8 - Critical Pin Retainer Bolts

Crit i cal pin re tainer bolts have lock tab wash ers fit -

ted, they should all be pres ent and not dam aged in

any way.

page 9 - 4

Rev A

EPV16 – 13642-1

9. Pre-operational Inspection

DANGER

DANGER