21

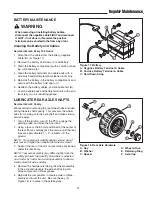

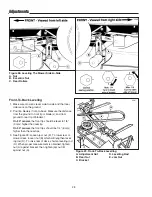

Figure 17. Battery

A. Negative Battery Terminal & Cable

B. Positive Battery Terminal & Cable

C. Hold Down Strap

BATTERY MAINTENANCE

Cleaning the Battery and Cables

Service Interval: Every 100 Hours

1. Disconnect the cables from the battery, negative

cable first (A, Figure 17).

2. Remove the battery hold-down (C) and battery.

3. Clean the battery compartment with a solution of bak-

ing soda and water.

4. Clean the battery terminals and cable ends with a

wire brush and battery terminal cleaner until shiny.

5. Reinstall the battery in the battery compartment, and

secure with the battery hold down (C).

6. Reattach the battery cables, positive cable first (B).

7. Coat the cable ends and battery terminals with petro-

leum jelly or non-conducting grease.

Regular Maintenance

WARNING

When removing or installing battery cables,

disconnect the negative cable FIRST and reconnect

it LAST. If not done in this order, the positive

terminal can be shorted to the frame by a tool.

C

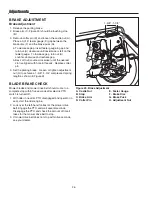

LUBRICATE REAR AXLE SHAFTS

Service Interval: Yearly

We recommend removing the rear wheel hubs and lubri-

cating the axle shafts yearly. This prevents the wheel

hubs from seizing onto the axle shaft and makes future

service easier.

1. Turn off the ignition, turn off the PTO, engage the

parking brake, and block the front tires.

2. Using a jack or chain hoist positioned at the center of

the rear frame, carefully jack the unit up until the rear

tires are approximately 1" - 2" (2.5-5cm) off the

ground.

NOTE: For overall unit stability during service, do not

jack rear end higher than required for wheel removal.

3. Support the rear of the unit on jackstands positioned

under the rear frame.

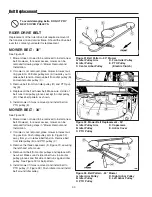

NOTE: Your axle assembly may differ slightly from the

assembly pictured: the quantity of washers is adjusted

on a tractor by tractor basis during assembly to allow a

small amount of axle end-play.

4. Remove the hardware retaining the wheel assembly

to the axle and lubricate the axle shaft using anti-

seize compound or lithium grease.

5. Reinstall the components in reverse order of disas-

sembly and lower the unit. Be sure the key (A,

Figure 18) is in place in the axle keyway.

Figure 18. Rear Axle Hardware

A. Key

D. Wheel & Hub

B. Washer

E. Retaining Ring

C. Spacer

F. Axle Cap

A

C

B

D

B

E

F

B

A