VR51-TFO26-A

Installation and Maintenance Manual

Original Instructions

VR51, Two Hand Control Valve

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

•

Read this manual before using the product, to ensure correct

handling, and read the manuals of related apparatus before use.

•

Keep this manual in a safe place for future reference.

•

These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

•

To ensure safety of personnel and equipment the safety instructions

in this manual and the product catalogue must be observed, along

with other relevant safety practices.

Caution

Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning

Indicates a hazard with a medium level of risk, which

if not avoided, could result in death or serious injury.

Danger

Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

Warning

•

The compatibility of pneumatic equipment is the responsibility of the

person who designs the pneumatic system or decides its

specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet

specific requirements.

•

Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be

performed by trained and experienced personnel.

•

Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only

be performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust

all residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc. (Supply air

into the system gradually to create back pressure, i.e. incorporate a

soft-start valve).

•

Do not use this product outside of the specifications. Contact

SMC if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if

the product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles, medical equipment, food and beverage,

recreation equipment, emergency stop circuits, press applications, or

safety equipment.

3) An application which has the possibility of having negative effects

on people, property, or animals, requiring special safety analysis.

Caution

•

Ensure that the air supply system is filtered to 5

μ

m.

2 Specifications

2.1 Specifications

Fluid Air

Operating pressure

0.25 to 1.0 MPa

Proof pressure

1.5 MPa

Ambient and fluid temperature

-5 to 60°C (with no freezing)

Flow characteristics

C[dm3/(s·bar)]

b

Cv

Operating frequency Max

10cpm

Operating frequency Min

Once every 30 days

Vibration & shock resistance

Do not use in a vibration environment

Environment

Indoor use only

P to A

0.3

-

-

A to R

1.0

0.12

0.25

Metric Ø6

Port size

Inch Ø1/4

Applicable tube material

Note)

Nylon, Soft nylon, Polyurethane,

Flame resistant (FR) soft nylon,

FR double layer,

FR double layer polyurethane

Weight 340g

Silencer

Part No.: AN101-01

Accessory

option

Bracket

Part No.: VR51B

Note) In the case of soft nylon or polyurethane tubing, use caution when

the maximum operating pressure of the tubing is used.

2.2 Features

•

When there is a time delay of less than 0.5 seconds between the two

air signal inputs, the VR51 provides an output signal.

•

VR51 output stops when one of the two air signal inputs stops.

•

Two simultaneous air signals resets the output.

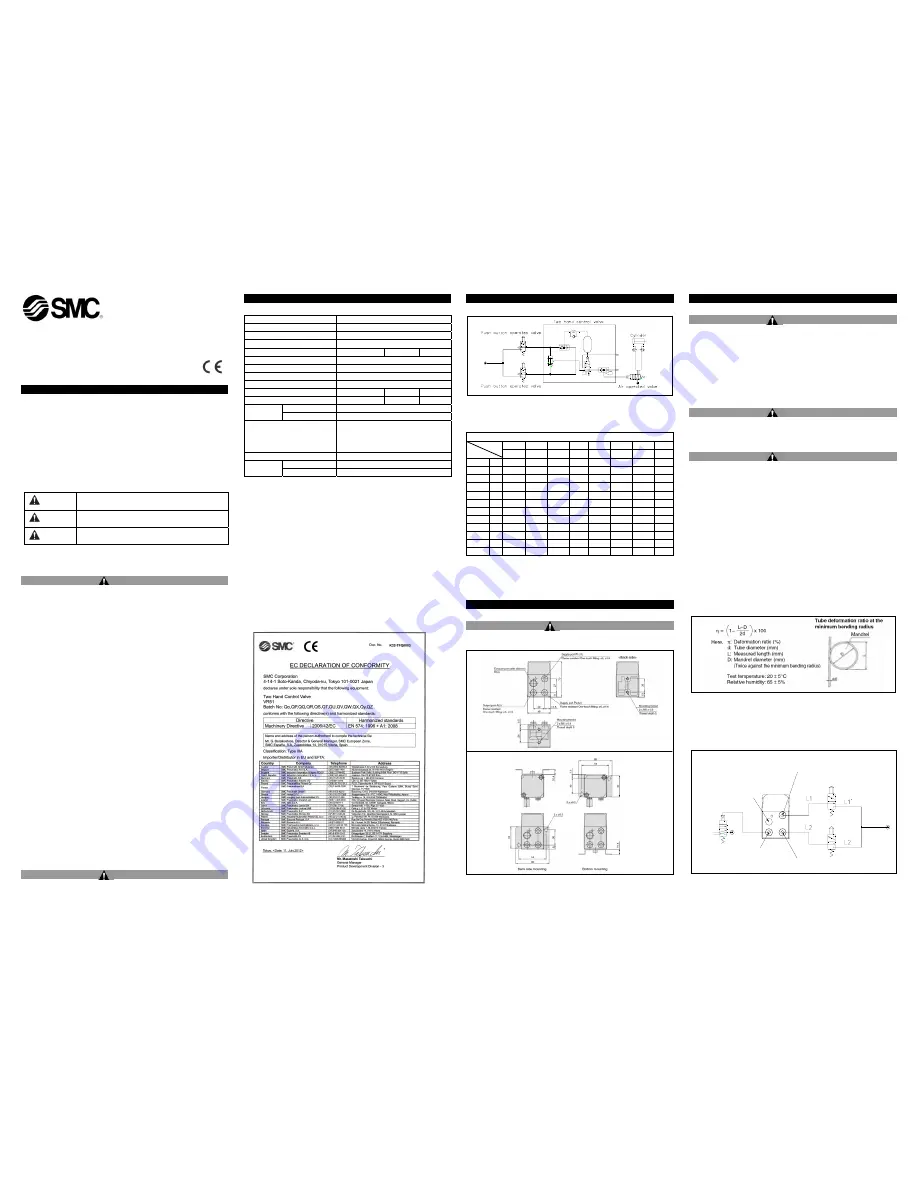

2.3 Declaration

of

Conformity

A sample Declaration of conformity (DoC) for this product is shown below.

An actual DoC is supplied with each product.

2 Specifications (Continued)

2.4 Typical

Circuit

2.5 Production batch code

The production batch code printed on the label indicates the month and

year of production as shown in the following table:

Production batch codes

2010 2011 2012 … 2021 2022 2023 …

Year

Month

H I J …

Z A B …

Jan O

oo Po Qo … Zo Ao Bo …

Feb P oP PP QP … ZP AP BP …

Mar Q

oQ PQ QQ … ZQ AQ BQ …

Apr R

oR PR QR … ZR AR BR …

May S oS PS QS … ZS AS BS …

Jun T

oT PT QT … ZT AT BT …

Jul U

oU PU QU … ZU AU BU …

Aug V oV PV QV … ZV AV BV …

Sep W

oW PW QW … ZW AW BW …

Oct X

oX PX QX … ZX AX BX …

Nov Y oy Py Qy … Zy Ay By …

Dec Z oZ PZ JZ … ZZ AZ BZ …

Note that lowercase letters are used in some instances.

3 Installation

3.1 Installation

Warning

•

Do not install the product unless the safety instructions have been

read and understood.

Note) Order the silencer separately, see section 2.

3 Installation (Continued)

3.1 Environment

Warning

•

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•

Do not use in an explosive atmosphere.

•

Do not expose to direct sunlight. Use a suitable protective cover.

•

Do not install in a location subject to vibration or impact. Check the

product specifications.

•

Do not mount in a location exposed to radiant heat.

•

Employ suitable protective measures in locations where there is

contact with oil or welding spatter etc.

Caution

•

Avoid using in places where there is splashing oil, coolant or water.

In addition, avoid using where dust may adhere.

3.2 Piping

Warning

•

Before piping make sure to clean up chips, cutting oil, dust etc.

•

When connecting piping, consult the instruction manual and use

caution to avoid incorrect piping.

•

Connect tubing with a longer length than required to prevent torsion,

stretching or moment loads. Damage of the fittings or flattening, as

well as bursting or releasing of the tubing may occur if the instructions

are not followed.

•

Tubing connected to the VR51 should be used at more than its

minimum bend radius. If used under the minimum bend radius,

bending or flattening of the tubing may occur.

The minimum bend radius is measured in accordance with JIS B

8381-1995.

JIS specifies the tubing deformation ratio measured at the

minimum bend ratio to be 25% or less.

*Except for the TU, TIUB, TUH, TRBU, TAU and TUS series

Tube deformation ratio at the minimum bend radius is obtained by the following formula, based on

tube and mandrel diameter

•

Use the same control valves for each input port.

•

Use tubing of the same length and diameter between the VR51 and

each control actuating device: L2=L1, L2’=L1’.

•

Operate the control valves from the same pressure source.

3.3 Piping Length for Secondary Side

Bracket mounting dimensions

EXHAUST PORT:R(4)

OUTPUT PORT:A(2)

SUPPLY PORT:P2(12)

SUPPLY PORT:P1(11)

Output Port: A(2)

Supply Port: P2(12)

Exhaust Port: R(4)

Supply Port: P1(11)