Wersja 1.00

Data edycji: 16.09.2022 r.

Strona 21 z 35

Dokumentacja techniczno-ruchowa

KWP-P-E

7.3.

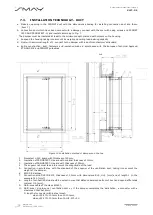

INSTALLATION TECHNOLOGY - DUCT

a.

Make an opening in the PROMAT duct with the dimensions allowing for installing connection duct into them.

(item 7),

b.

Connection duct which have been connect with a damper, connect with the duct with using screws and PROMAT

L500 AND PROMATECT-H, and insulate according to Fig. 7.

The damper must be insulated at least to the minimum depth marked with cutouts on the housing.

c.

Suspend the housing taking into account its weight and ceiling load-bearing capacity

d.

Duct with a minimal length of C

connect to the damper with a duct manufacturer’s standard.

e.

Entire construction: duct, fasteners and insulation made in accordance with the European Technical Approval

ETA-06/0218 and PROMAT guidelines

Figure 10.Installation method of dampers on the tee

1.

Promatect L-500 board with thickness of 50mm,

2.

Insulation of PROMATECT-H board with minimal thickness of 10mm,

3.

Insulation of PROMATECT-H board with thickness of 25mm,

4.

The support rail must take into account the magnitude of the load

5.

Connection in accordance with the standard of the supplier of the ventilation duct, taking into account the

weight of the damper,

6.

KWP-P-E damper,

7.

Connection stub DX51D-Z275 thickness of 1,5mm with dimensions B+5, H+5 [mm] and of length L (in the

example 165 [mm]),

8.

Length of connection stub should be select in way that distance between bottom of duct and open baffle totals

minimal 100 [mm],

9.

Multi-zone cable of the class EIS120,

10.

Multi-zone / single-zone / ventilation duct or, if the damper completes the installation, a connector with a

steel mesh 19x19x1,4mm.

C- length of connector with a steel mesh,

when H/2-270<100mm then

C≥100mm,

when H/2-270>100mm then

C≥H/2

-270+50