Version 6.00

Date of editing: 16.09.2022 r.

Page 8 z 18

Installation manual

KWP-O-ES

IV.

INSTALLATION TECHNOLOGY

–

STRUCTURES THICKER THAN 135 mm

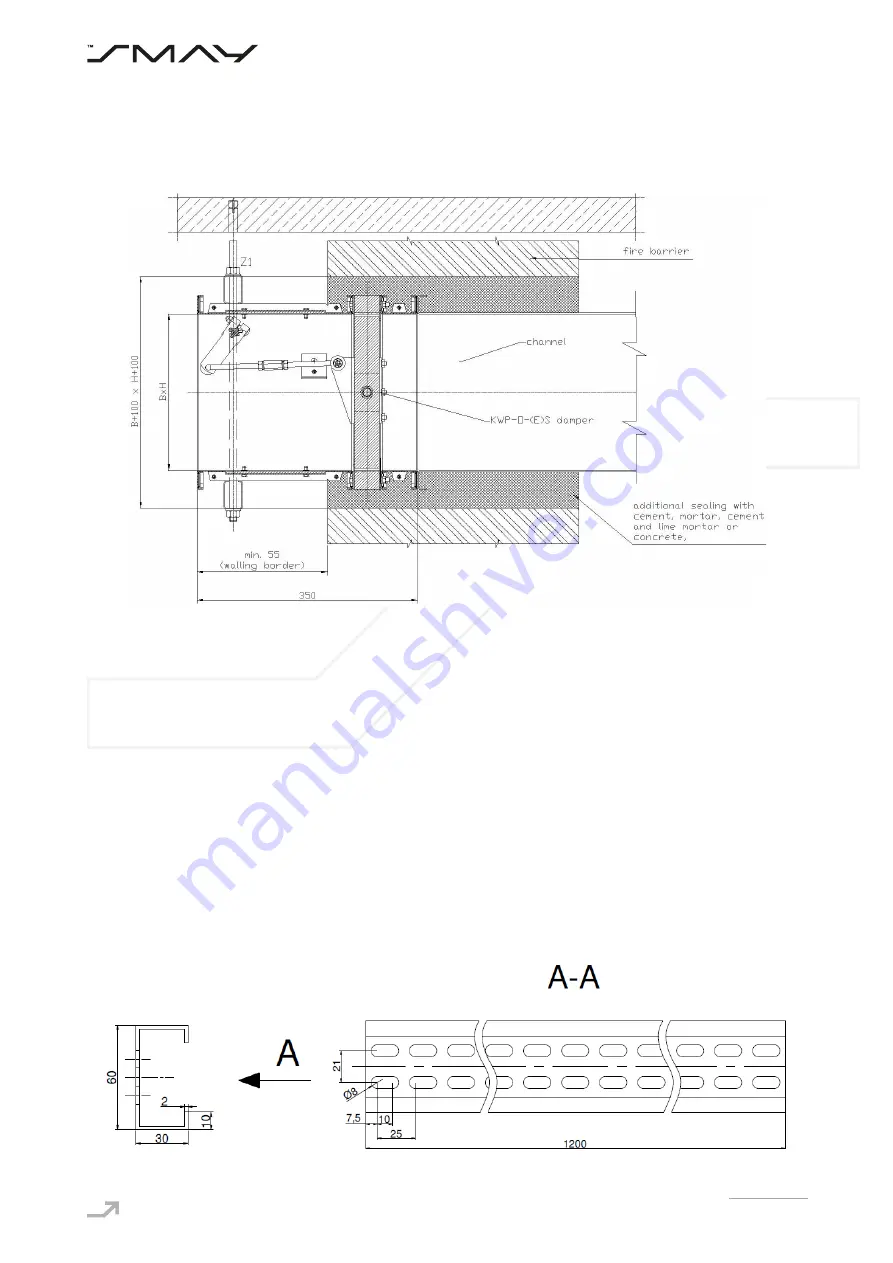

The KWP-O-

E(S) damper can be installed also in horizontal compartments thicker than length of damper’s body. In

this case, ventilation ducts are going to be partially inbuilt in the fire compartment (Figure 9).

Figure 7. Installation method of fire dampers KWP-O in structures thicker than 135 mm

V.

INSTALLATION TECHNOLOGY FOR FIRE DAMPERS IN BATTERIES

The assembly of fire dampers in batteries is possible only after previous delivery of the information (at the stage of

ordering) about which fire dampers and in which arrangement (horizontal or vertical) would be installed in a wall, in

order to prepare suitable opening for self-tapping screws in the fire damper body.

There are two possibilities of realizing the order of fire damper batteries: basic and complete. First one covers the set

of fire dampers, assembly strips and complete set of self-tapping screws. The purchase of other materials needed such

as: intumescent gasket (PROMASEAL-PL PVC SK), mineral wool for thermal insulation (with minimum density of 60

kg/m

3

) and aluminum tape remains with the Customer. The secund variant provides for supply by the Manufacturer of

complete set of fire dampers and all the elements needed for installation.

The fire dampers are assembled into batteries with use of assembly strips with length of 1200 [mm]. In case when

total dimension of their battery is smaller than multiple of the length of the assembling strip, the last one should be

cut with angle grinder on the construction site to match the dimension of the battery (basic variant) or cut in

manufacturing facility by Manufacturer (complete variant)

Fire dampers should be marked with letters: A, B, C, D.

Figure 8. Connection strip