Version 6.00

Date of editing: 16.09.2022

r.

Page 20 of 30

Technical documentation

KWP-L

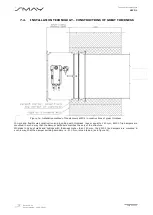

7.3.

INSTALLATION TECHNOLOGY

–

FLEXIBLE WALL

a.

Make an opening in the wall with the dimensions 100 [mm] (acceptable

80 ÷ 120 [mm])

greater than the

nominal dimensions of the fire damper = B+100 i H+100.

b.

Make a frame of two layers of GKF boards, 12,5 mm thick and the width relative to the width of opening,

mounting by screws

remembering to carefully seal the contact edges with a mastic:

Hilti Firestop Coating CP 673,

Promastop-Coating, Promaseal-Mastic Soudal Firesilicone B1 FR.

c.

Put the closed fire damper into the installation opening and support or suspend, in this way that the minimum

installation depth mark is on the plane of the flange surface.

d.

After setting the fire damper as described, fill the gap between the fire damper and the wall with non-flammable

mineral wool of high density, 100 kg/m

3

or more.

e.

Seal the place of filling with mineral wool using the sealing compounds given in pts.2

f.

Mount collar, both side of wall, made of GKF boards, 12,5 mm thick and 150 mm wide, using screws.

g.

After mounting the collar, remove the supports or suspensions, check the fire damper correct operation and

leave it in open position.

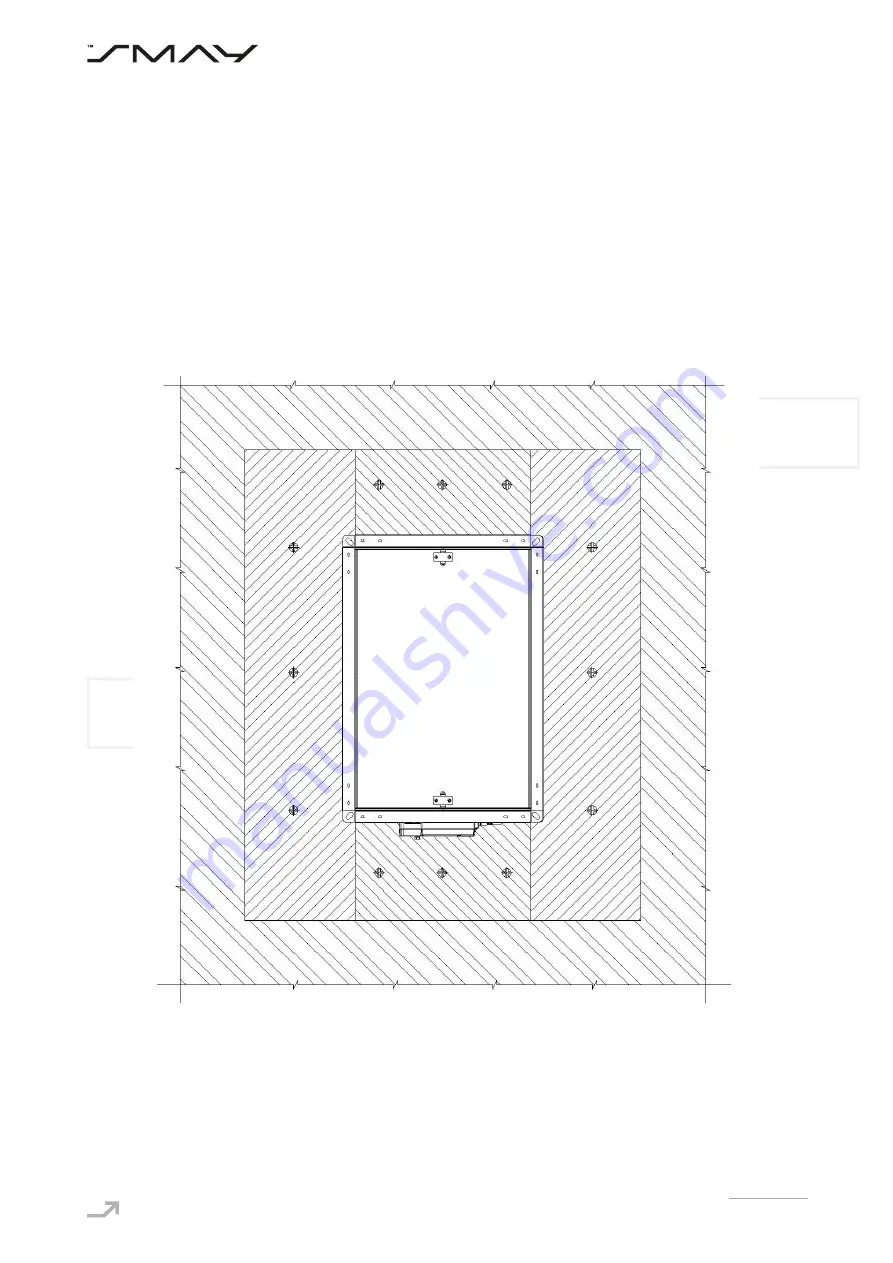

Figure 9.

Installation method of fire dampers KWP-L in flexible wall with vertical rotation axis of baffle

Содержание KWP-L

Страница 1: ...a Technical Documentation KWP L Fire Damper rectangular v https www smay eu ...

Страница 14: ...Version 6 00 Date of editing 16 09 2022 r Page 13 of 30 Technical documentation KWP L Technical data BF230 TN ...

Страница 15: ...Version 6 00 Date of editing 16 09 2022 r Page 14 of 30 Technical documentation KWP L Technical data BF24 TN ...