Routine Checks and Maintenance

9-3

7SA522 Manual

C53000-G1176-C119-2

9.2

Routine Checks

Routine checks of the characteristic curves or pick-up values of the protective ele-

ments are not necessary because they form part of the continuously supervised

firmware programs. The normally scheduled interval for plant maintenance can be

used for carrying out operational testing of the protective and control equipment. The

maintenance serves mainly to check the serial or hardwired interfaces of the device,

i.e. the coupling with the plant.

The steps listed below are recommended for routine checks. If a problem is detected

during these checks, refer to Section 9.4.

o

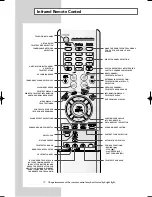

Verify that the green “RUN” LED is lit on the front panel and the red “ERROR” LED is

not.

o

Check that the states of the LEDs on the front panel give an accurate image of the

conditions of the device and the plant. Investigate any problems or uncertainties.

o

Press the

key. All of the LEDs should temporarily light except for the “ERROR”

LED. Only the LEDs indicating specific present conditions should remain lit.

o

Read the measurement values and compare them to an independent source to check

the measuring circuits of the . Refer to Sub-section 7.1.3 for assistance in reading the

measurement values.

o

Review the messages given under the

$QQXQFLDWLRQ

sub-menu. Be sure there are

no reports of unknown problems or abnormal occurrences related to the device, the

measuring circuits, or the power system. All information should be plausible. See Sub-

section 7.1.1.2 for help in reading the messages.

o

Perform a reset (reboot) of the device. A complete check of the hardware is done. The

device is effectively out of service during the reset, which lasts for about 10 to 15 sec-

onds. To perform the reset from the operator control panel, press the

key and use

the

and

keys to select the

'HYLFH5HVHW

under the

7(67',$*126(

sub-

menu. Press the

key, enter Password No. 4 for test and diagnostics, and answer

with

<HV

. During the reset, the “ERROR” and “RUN” LEDs are lit, the other LEDs flash,

and the display becomes blank. After a successful reset, the default display reappears

and the LEDs return to indicate normal operation. The device is then back in-service.

To perform the reset with , establish the

2QOLQH

mode, select

'HYLFH

in the menu

bar, and then

5HVHW

Enter the password for test and diagnostics; then

2.

.

o

Other testing can be done with DIGSI

®

4 on-line. In Hardware Test under Test, the

conditions of all of the binary inputs, binary outputs, and LEDs can be monitored. Com-

pare the indicated conditions with the actual conditions. Do not change the states of

the device components because the station is immediately affected!

o

The trip and close circuits for circuit breakers and other primary equipment can be ver-

ified with operator control actions. Other circuits can be checked as well. Refer to Sec-

tion 7.3 for details about system control.

Warning!

Changing of the states of the binary inputs, outputs, and LEDs must not be done with

test features during normal operation. Any such change immediately affects the inputs

and outputs of the device, and therefore the connected switching devices! This in-

cludes, for instance, non-interlocked primary switching!

LED

MENU

ENTER

Содержание siprotec 7SA522

Страница 20: ...7SA522 Manual C53000 G1176 C119 2 ...

Страница 64: ...7SA522 Manual C53000 G1176 C119 2 ...

Страница 89: ...SIPROTEC 4 Devices 4 25 7SA522 Manual C53000 G1176 C119 2 Figure 4 20 CFC Logic example ...

Страница 408: ...7SA522 Manual C53000 G1176 C119 2 ...

Страница 456: ...7SA522 Manual C53000 G1176 C119 2 ...

Страница 516: ...7SA522 Manual C53000 G1176 C119 2 ...

Страница 620: ...Appendix B 48 ...