6.11.3

Importing and editing a DXF file in the editor

6.11.3.1

General procedure

● Creating and opening a G-code or ShopMill program

● Calling "Contour milling" cycles and creating a "New contour"

- OR -

● Calling "Positions / position pattern" from the "Drill" cycle

● Importing a DXF file

● Select the contour or drilling positions in the DXF file or CAD drawing and click "OK" to

accept the cycle

● Add program record with "Accept" to the G-code or ShopMill program

6.11.3.2

Specifying a reference point

Because the zero point of the DXF file normally differs from the zero point of the CAD drawing,

specify a reference point.

Procedure

1.

The DXF file is opened in the editor.

2.

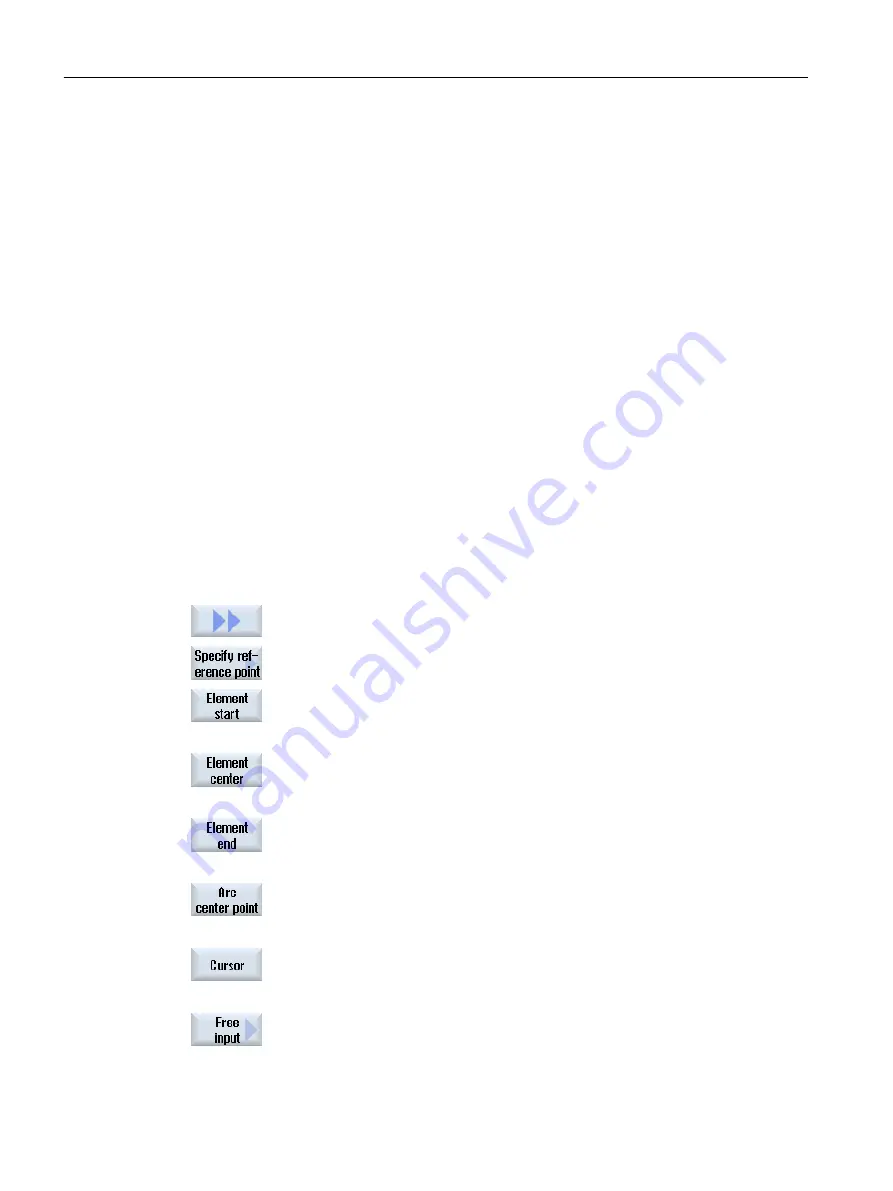

Press the ">>" and "Specify reference point" softkeys.

3.

Press the "Element start" softkey to place the zero point at the start of the

selected element.

- OR -

Press the "Element center" softkey to place the zero point at the center

of the selected element.

- OR -

Press the "Element end" softkey to place the zero point at the end of the

selected element.

- OR -

Press the "Arc center" softkey to place the zero point at the center of an

arc.

- OR -

Press the "Cursor" softkey to define the zero point at any cursor position.

- OR -

Press the "Free input" softkey to open the "Reference Point Input" window

and enter the values for the positions (X, Y) there.

Machining the workpiece

6.11 Working with DXF files

Milling

230

Operating Manual, 08/2018, 6FC5398-7CP41-0BA0

Содержание SINUMERIK 828D Turning

Страница 68: ...Introduction 2 4 User interface Milling 68 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 162: ...Setting up the machine 4 12 MDA Milling 162 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 270: ...Machining the workpiece 6 17 Setting for automatic mode Milling 270 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 278: ...Swivel combination 45 90 Simulating machining 7 1 Overview Milling 278 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 294: ...Simulating machining 7 9 Displaying simulation alarms Milling 294 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 316: ...Generating a G code program 8 10 Measuring cycle support Milling 316 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 684: ...Collision avoidance 12 2 Set collision avoidance Milling 684 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 746: ...Tool management 13 16 Working with Multitool Milling 746 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 830: ...Alarm error and system messages 15 9 Remote diagnostics Milling 830 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 846: ... Working with Manual Machine 16 7 More complex machining Milling 846 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 870: ...HT 8 840D sl only 18 5 Calibrating the touch panel Milling 870 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 890: ...Easy Message 828D only 20 7 Making settings for Easy Message Milling 890 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 924: ...Edit PLC user program 828D only 23 8 Searching for operands Milling 924 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 925: ...Appendix A A 1 840D sl 828D documentation overview Milling Operating Manual 08 2018 6FC5398 7CP41 0BA0 925 ...