Velocities, Setpoint/Actual Value Systems, Closed-Loop Control (G2)

7.3 Setpoint/actual-value system

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

129

If settings beyond the limit are made, the value in MD36210 is used as the limiter, an alarm

is output and the axes brought to a halt. See Chapter "Axis monitoring functions" for more

details.

With an analog spindle the maximum speed that can be output is limited by the maximum

setpoint output voltage of 10 V. The value in MD36210 CTRLOUT_LIMIT should not be

greater than the speed value that is reached at this voltage (100%).

Note

For special considerations for controlling a spindle, see Chapter "Spindles (S1)".

7.3.5

Actual-value processing

Actual-value resolution

In order to be able to create a correctly closed position closed-loop control, the control

system must be informed of the valid actual-value resolution.

Depending on the type of axis (linear axis, rotary axis/spindle, analog spindle) and the type

of actual-value resolution (direct, indirect), the following machine data must be

parameterized to calculate the actual-value acquisition for the main applications:

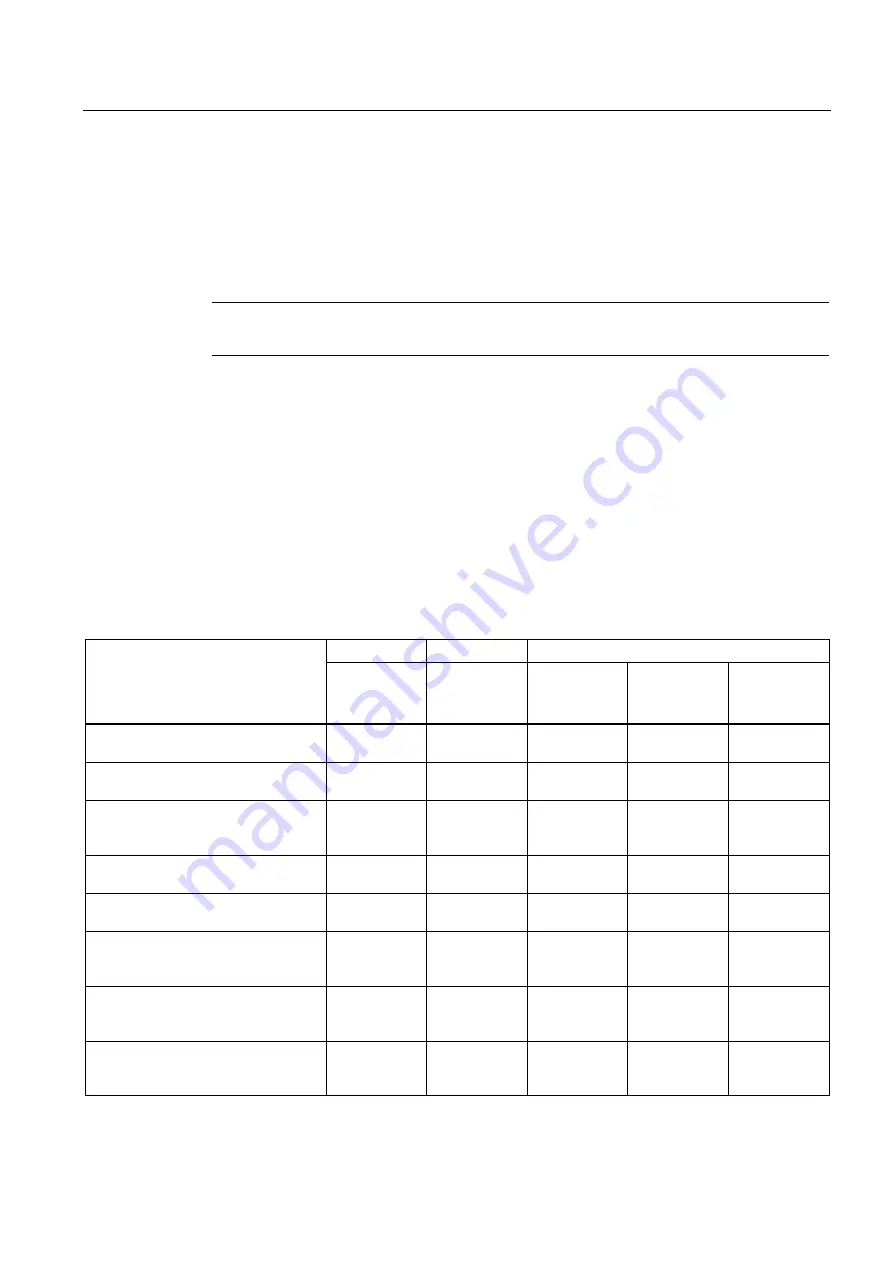

Linear axis

Rotary axis

Spindle

Machine data

Encoder on

motor

Encoder on

motor

Encoder on

motor

Encoder on

machine

Without

measuring

system

MD30200 NUM_ENCS

(number of encoders)

1

1

1

1

0

MD30300 IS_ROT_AX

(rotary axis)

0

1

1

1

1

MD31040 ENC_IS_DIRECT[0]

(encoder is connected directly at the

machine)

0

0

0

1

1

MD31020 ENC_RESOL[0]

(encoder pulses per revolution)

Pulses/rev

Pulses/rev

Pulses/rev

Pulses/rev

-

MD31030 LEADSCREW_PITCH

(leadscrew pitch)

mm/rev.

-

-

-

-

MD31080

DRIVE_ENC_RATIO_NUMERA[n]

(measuring gearbox numerator)

1

1

1

load revs

-

MD31070

DRIVE_ENC_RATIO_DENOM[n]

(measuring gearbox denominator)

1

1

1

encoder revs

-

MD31060

DRIVE_AX_RATIO_NUMERA[n]

(load gearbox numerator)

motor revs

motor revs

motor revs

See

note *)

-

Содержание SINUMERIK 802D sl

Страница 58: ...Axis Monitoring A3 2 6 Data lists Turning Milling Nibbling 58 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 84: ...Travel to fixed stop F1 5 6 Data lists Turning Milling Nibbling 84 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 114: ...Gantry axes G1 6 8 Data lists Turning Milling Nibbling 114 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 260: ...Measurement M5 13 6 Data lists Turning Milling Nibbling 260 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 314: ...Positioning Axes P2 17 3 Data lists Turning Milling Nibbling 314 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 332: ...Reference Point Approach R1 18 6 Data lists Turning Milling Nibbling 332 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 340: ...Rotary Axes R2 19 4 Data lists Turning Milling Nibbling 340 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 368: ...Spindle S1 20 9 Data lists Turning Milling Nibbling 368 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 390: ...Tangential Control T3 22 5 Data lists Turning Milling Nibbling 390 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 422: ...Feed V1 24 4 Data lists Turning Milling Nibbling 422 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 440: ...Appendix A 2 Overview Turning Milling Nibbling 440 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...

Страница 458: ...Glossary Turning Milling Nibbling 458 Function Manual 11 2012 6FC5397 1CP10 5BA0 ...