4. When positioning the machine, ensure that a uniform axial gap (y→0) is maintained around

the coupling.

5. Fix the machine to the foundation. The choice of fixing elements depends on the foundation

and is the plant operator's responsibility.

'

[

\

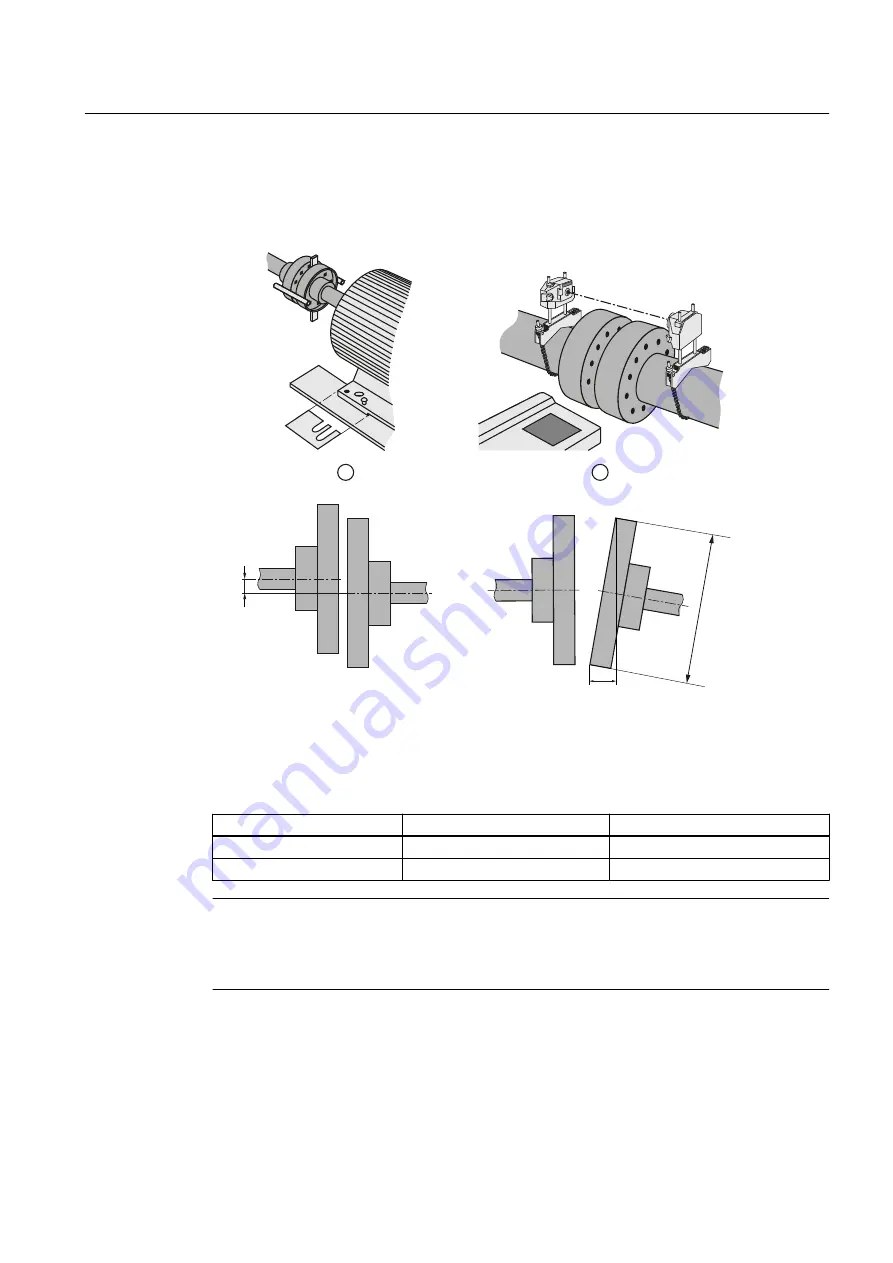

①

Plates placed under the motor for alignment

②

Laser alignment

Figure 5-4

Schematic diagram: Aligning the machine to the driven machine

Table 5-2

Permissible deviations for aligning the machine with flexible coupling

Max. speed n

max

Max. parallel offset x

Max. angular offset y

n

max

≤ 1500 rpm

x

max

= 0.08 mm

y

max

= 0.08 mm / 100 mm ∅ D

1500 rpm <

n

max

≤ 3600 rpm

x

max

= 0.05 mm

y

max

= 0.05 mm / 100 mm ∅ D

Note

Machine expansion

When performing alignment, make allowance for the thermal expansion of the machine due to

rising temperature.

See also

Tightening torques for screw and bolt connections (Page 165)

Assembly

5.4 Installing the machine

SIMOTICS FD 1LH1

Operating Instructions 01/2019

67

Содержание SIMOTICS FD 1LH1

Страница 2: ...23 01 2019 19 26 V11 01 ...

Страница 28: ...Description SIMOTICS FD 1LH1 28 Operating Instructions 01 2019 ...

Страница 72: ...Assembly 5 5 Connecting the cooling water supply SIMOTICS FD 1LH1 72 Operating Instructions 01 2019 ...

Страница 122: ...Operation 8 10 faults SIMOTICS FD 1LH1 122 Operating Instructions 01 2019 ...

Страница 140: ...Maintenance 9 2 Corrective Maintenance SIMOTICS FD 1LH1 140 Operating Instructions 01 2019 ...

Страница 162: ...Disposal 11 5 Disposal of components SIMOTICS FD 1LH1 162 Operating Instructions 01 2019 ...

Страница 164: ...Service and Support SIMOTICS FD 1LH1 164 Operating Instructions 01 2019 ...

Страница 168: ...Quality documents SIMOTICS FD 1LH1 168 Operating Instructions 01 2019 ...

Страница 173: ......