Criteria for selecting rolling bearing greases

High quality ISO‑L‑X BDEA3 lubricating grease according to ISO 6743-9 and K3K‑20

lubricating grease according to DIN 51825 with lithium soap as a thickener and an upper

service temperature of at least +130° C / +266° F are permissible for standard applications

without special requirements.

● The technical data of the rolling bearing grease must be suitable for the application.

● Only use the grease type that is specified on the lubricant plate.

● If the operating conditions differ from those mentioned, other lubricating greases may only

be used after prior consultation with the manufacturer.

● If lubricating greases other than those named on the lubricant plate are used, it cannot be

guaranteed that they are compatible with the complete system.

– If you use lubricating greases that satisfy only the minimum requirements of DIN 51825

or ISO 6743-9, then reduce the lubrication intervals by half or adapt them as appropriate.

– If in doubt, consult the manufacturer.

● The lubrication properties will be impaired if you mix different lubricating greases. This can

result in material damage. Only the manufacturer can provide a guarantee for the miscibility

of particular lubricating greases.

● The lubricating grease must satisfy the criteria listed in the table below and must match the

operating conditions. If different special lubricating greases are stated on the lubricant plate,

then different criteria apply.

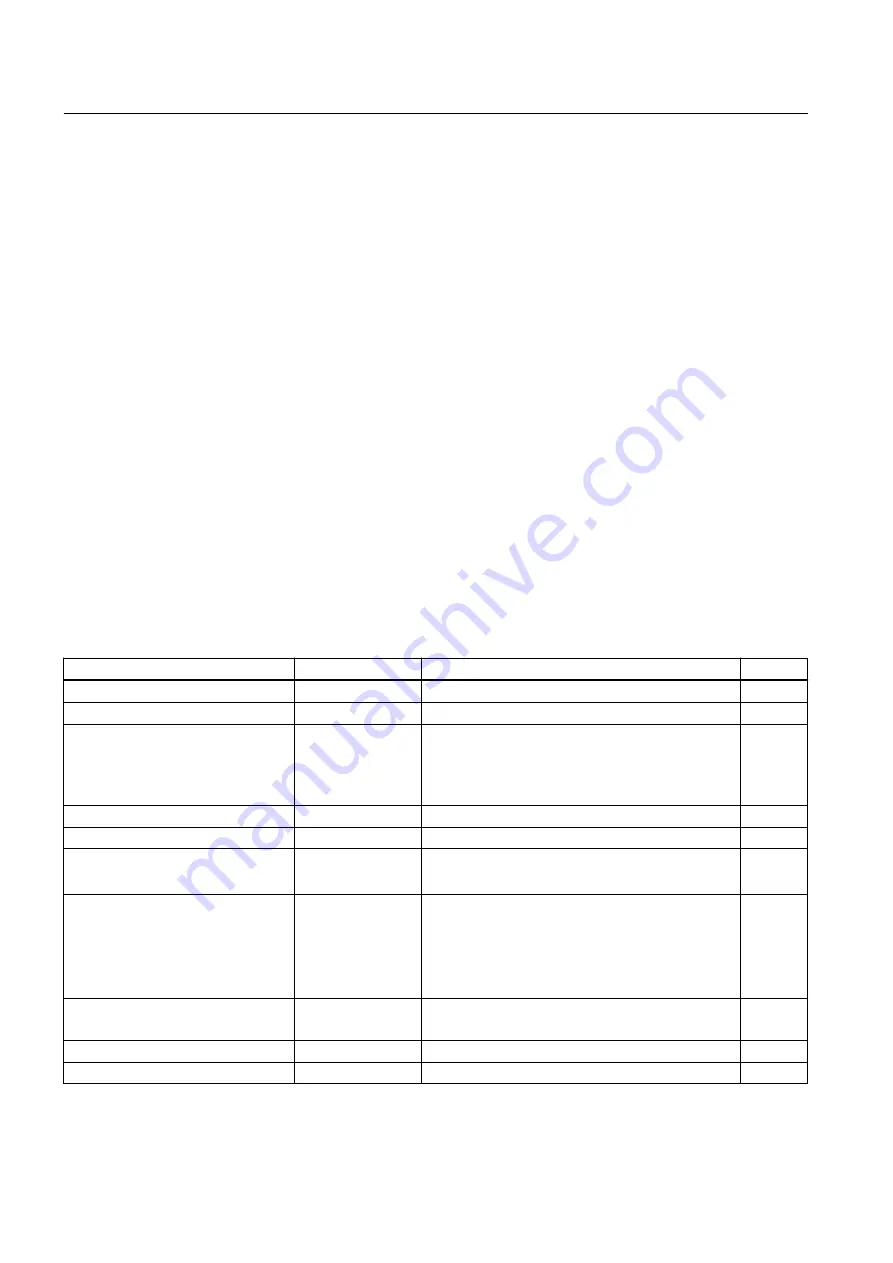

Table 9-3

Criteria for selecting rolling bearing greases

Criteria

Standard

Property, characteristic value

Unit

Type of base oil

-

Mineral oil

-

Thickener

-

Lithium

-

Consistency in accordance with

NLGI class

DIN 51818

● "3" for vertical and horizontal types of

construction

● "2" alternatively for horizontal type of

construction with reduced lubrication interval

-

Operating temperature range

-

At least -20° C ... +130° C

°C

Dropping point

DIN ISO 2176

At least +180° C

°C

Basic oil viscosity

DIN 51562-1

● Approx. 100 mm²/s at 40 °C

● Approx. 10 mm²/s at 100 °C

mm²/s

Additives

-

● Anti-Oxidation (AO), Anti-Wear (AW)

● No solid lubricants

● Alternatively: Extreme-pressure (EP) only after

prior consultation with grease and bearing

manufacturers

-

FE9 test: A/1500/6000

DIN 51821-1/-2

F10 ≥50 h at +130 °C

F50 ≥100 h at +130 °C

H

Behavior in the presence of water

DIN 51807

0 or 1 at a test temperature of +90° C

-

Corrosive effect on copper

DIN 51811

0 or 1 at a test temperature of +120° C

Korr.°

Maintenance

9.1 Inspection and maintenance

SIMOTICS FD 1LH1

128

Operating Instructions 01/2019

Содержание SIMOTICS FD 1LH1

Страница 2: ...23 01 2019 19 26 V11 01 ...

Страница 28: ...Description SIMOTICS FD 1LH1 28 Operating Instructions 01 2019 ...

Страница 72: ...Assembly 5 5 Connecting the cooling water supply SIMOTICS FD 1LH1 72 Operating Instructions 01 2019 ...

Страница 122: ...Operation 8 10 faults SIMOTICS FD 1LH1 122 Operating Instructions 01 2019 ...

Страница 140: ...Maintenance 9 2 Corrective Maintenance SIMOTICS FD 1LH1 140 Operating Instructions 01 2019 ...

Страница 162: ...Disposal 11 5 Disposal of components SIMOTICS FD 1LH1 162 Operating Instructions 01 2019 ...

Страница 164: ...Service and Support SIMOTICS FD 1LH1 164 Operating Instructions 01 2019 ...

Страница 168: ...Quality documents SIMOTICS FD 1LH1 168 Operating Instructions 01 2019 ...

Страница 173: ......