UM353-1

Function Blocks

March 2003

3-31

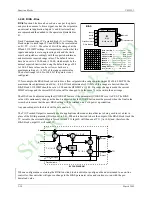

3.2.22 BATOT - Batch Totalizer

BATOT

function blocks can be used on a one per loop

basis and integrate an analog input. Each provides an

output signal representing a total integrated value over the

time base selected. For example, if the time base is

minutes and input A is 5.0 for 60 minutes, output TL

would equal 300.0. The total can be displayed on the

operator faceplate as <loop tag>.T if the configuration

parameter DISP TOT is set to YES. A 6-character

maximum name (e.g. GAL) is entered in configuration

under TOT UNIT to identify the totalizer units.

Input S asserted high (1) will stop the integrator action.

Input R will cause the integrator function to reset to the

initial value (INIT VAL). These inputs do not affect the

P

u

L

se output. The integrator output is summed with the

INITial VALue entered in configuration to provide the

count total. The INIT VAL is used as the total when the

BATOT is reset.

DIR ACT set to YES will cause the integrator to increase

its output while NO will cause the integrator output to

decrease. When INIT VAL is set to a predetermined batch

amount, decreasing action will provide a count down

counter. This is sometimes preferred since the count

output then represents the amount remaining in a batch.

ZDO is used for setting a small positive value, insuring that the integrator will stop when the flow is shut off, which

might not otherwise happen if a flowmeter zero is out of calibration.

The function block has two trip presets: PRESET 1 and PRESET 2. These can be set to cause a high output (1)

from A1 or A2 when the count total equals or exceeds the preset values. The preset values, entered in

configuration, can also be set using the QUICK button if the parameter QUICKSET has been set to YES. The QS

DPP parameter allows fixing the decimal point during quickset to speed up changes to these settings. A parameter

value with no decimal point position, the default, is for applications dealing with the totalizer count as whole units.

An external preset can be used by providing an input to T1 and/or T2 and when used, the internal preset will be

ignored. If an external preset is used, the value can be viewed but not changed in QUICKSET.

The action of the presets is also determined by the action setting of the integrator. When DIR ACT is set to YES

the presets will be direct acting and will cause outputs A1 or A2 to go high when the integrated total is equal to or

higher than the preset. If set to NO the total will cause A1 or A2 to go high when the total is equal to or lower than

the preset. The actual preset value is available on outputs T1 and T2.

The function block can also provide a pulse output to drive a remote counter. The pulse output function integrates

the input signal using the same time base and output pulses at a rate determined by the PUL SCAL configuration

parameter. This parameter determines the change to the integrator total that must occur to cause a new output pulse.

In the above example, if PUL SCAL equals 10, a total of 30 pulses will have occurred in the same time period. The

PUL SCAL value is also the multiplier that would be used to read the exact value of gallons to a remote counter.

The pulse output function operates on the absolute value of the analog input. When both negative and positive

values are to be totalized, a CoMParator block can be used to sense the polarity of the analog input and the CMP

output can then indicate a direction to the counter.

Be sure that the PUL SCAL setting does not require a pulse rate output greater than the scan cycle time of the

controller under the maximum input conditions. Using the same example, if the maximum A input is 60.0 and the

cycle time is 0.1 sec, the maximum required pulse rate is 0.1/sec. The condition is satisfied since the maximum

A

nalog Input

BATCH TOTALIZER

B

T

ime

B

ase

(S)

.........1-sec,2-min,3-hr,4-day,5-wk

(2)

DIR

ect

ACT

ing

(S)

................................. NO/YES

(YES)

Z

ero

D

rop

O

ut

(S)

........................................ Real

(0.0)

TL

T

ota

L

TOTALIZER

BATOT

ESN = 000

T

A

S

R

BATCH

S

top

R

eset

P

u

L

se

I N P U T

O

E

xec.

S

eq.

N

o.

(H)

............................. 001 to 250

L

A

D

1

P

T O T

C K S E T

I

I

N

N

P

P

U

U

T

T

A

S

R

S

E

N

INPUT R

(H)

......................

loop tag.block tag.output (null)

INPUT S

(H)

.......................

loop tag.block tag.output (null)

INPUT EC

(H)

....................

loop tag.block tag.output (null)

DISP

lay

TOT

al

(H)

................................. NO/YES

(YES)

QUICK SET

presets

(S)

..........................NO/YES

(YES)

PRESET 2

(S)

.............................................. Real

(0.0)

PRESET 1

(S)

.............................................. Real

(0.0)

TOT

alizer

UNIT

s

(S)

....................... 6 Char ASCII

(null)

N I T

V

T

I

N

I

INIT

ial

VAL

ue

(S)

......................................... Real

(0.0)

A C T

R

I

D

U

O

Z

T

E

S

E

R

P

T

E

S

E

R

P

2

S

I

D

I

U

Q

PL

A1

Al

arm

1

P U L

S C

L

A

PUL

se

SCAL

ing

(S)

.................................... Real

(1.0)

T

T

I

I

N

N

P

P

U

U

T

T

1

2

INPUT T2

(H)

.....................

loop tag.block tag.output (null)

INPUT T1

(H)

......................

loop tag.block tag.output (null)

T1

T2

T1

T

rip

1

A2

T2

T

rip

2

T

rip

1

(external)

T

T

Al

arm

2

T

rip

2

(external)

E

xt.

C

ount In

EC

I N P U T

E C

INPUT A

(H)

......................

loop tag.block tag.output (null)

P

ower

U

p

LAST

(S)

............................... NO/YES

(YES)

T

S

A

L

U

P

Q

uick

S

et presets

D

ec.

P

t.

P

os.

(H)

.. 0.0.0.0.0.0.

(0.)

Q

D

P

P

S

StockCheck.com

Содержание Moore 353

Страница 2: ...S t o c k C h e c k c o m ...

Страница 14: ...Contents UM353 1 xii March 2003 S t o c k C h e c k c o m ...

Страница 24: ...Introduction UM353 1 March 2003 1 10 S t o c k C h e c k c o m ...

Страница 152: ...LonWorks Communications UM353 1 March 2003 5 4 S t o c k C h e c k c o m ...

Страница 164: ...Network Communications UM353 1 6 12 March 2003 S t o c k C h e c k c o m ...

Страница 246: ...Operation UM353 1 March 2003 9 8 S t o c k C h e c k c o m ...

Страница 254: ...Controller and System Test UM353 1 March 2003 10 8 S t o c k C h e c k c o m ...

Страница 282: ...Circuit Description UM353 1 March 2003 13 4 S t o c k C h e c k c o m ...

Страница 298: ...Model Designation and Specifications UM353 1 March 2003 14 16 S t o c k C h e c k c o m ...

Страница 302: ...Abbreviations And Acronyms UM353 1 15 2 March 2003 S t o c k C h e c k c o m ...

Страница 304: ...Warranty UM353 1 W 2 March 2003 S t o c k C h e c k c o m ...