Siemens AG

SPB7-250.815.06.02.02

MAMMOMAT Novation DR

12.05

CS SD 24

Important Notes

15

Page 15 of 116

Medical Solutions

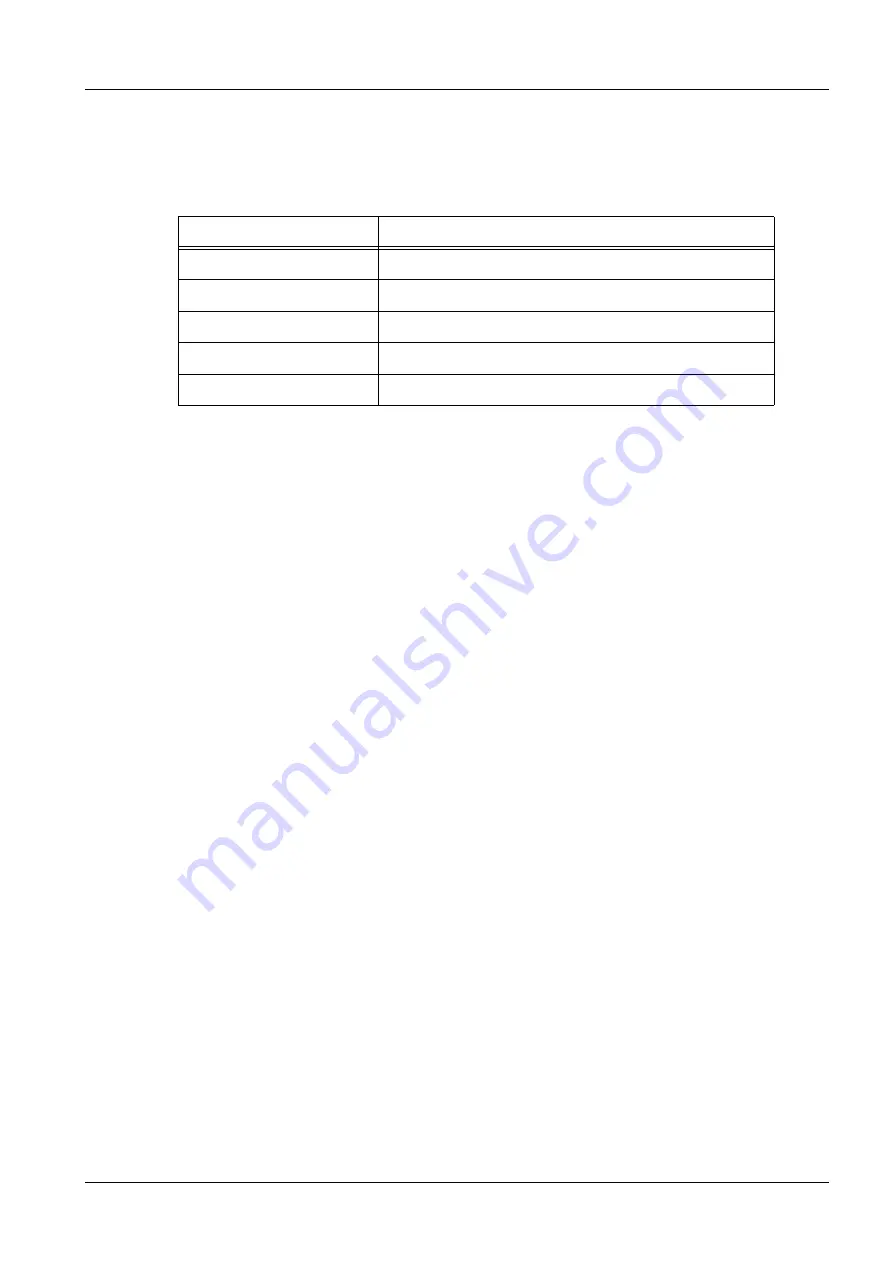

Delay times between two exposures

0

The delay times listed below must be followed to prevent the tube from overheating.

Tab. 4

Delay times between two exposures

Exposure mAs value

Delay time between two exposures (seconds)

max. 100

min. 15

max. 200

min. 30

max. 300

min. 45

max. 400

min. 60

max. 500

min. 75