LMV

Series

Technical

Instructions

Document

No.

LV5

‐

1000

SCC

Inc.

Page

29

Section

6

Considerations

when

Using

O

2

Trim

with

FGR

Some

burners

use

a

high

percentage

of

FGR

(FGR

flow

compared

to

air

flow)

to

lower

NOx

emissions.

Since

flue

gases

change

in

%O

2

and

are

being

drawn

back

into

the

blower

in

significant

quantities,

these

types

of

burners

are

inherently

more

difficult

to

trim

the

%O

2

in

the

stack.

The

reason

behind

this

increased

difficulty

is

the

oxygen

content

of

the

air

/

FGR

mixture

is

dependent

on

the

%O

2

in

the

stack,

which

adds

another

dynamic

variable

into

the

system.

On

a

burner

without

FGR,

the

oxygen

content

of

the

air

at

the

blower

intake

is

always

a

constant

20.9%

O

2

.

Naturally,

a

larger

percentage

of

FGR

(20%)

has

the

potential

to

vary

the

oxygen

content

of

the

air

/

FGR

mixture

at

the

blower

intake

more

than

a

small

percentage

of

FGR

(5%)

would.

Moreover,

a

large

percentage

of

FGR

can

change

the

oxygen

content

of

the

air

/

FGR

mixture

at

the

blower

intake

in

a

way

that

can

set

up

a

"cycle

of

intensification".

An

example

of

this

cycle

is

below:

1.

The

%O

2

in

the

stack

increases

for

some

reason.

2.

The

%O

2

in

the

FGR

also

increases.

3.

The

oxygen

content

of

the

air

/

FGR

mixture

at

the

blower

intake

increases,

which

increases

the

%O

2

in

the

stack

even

more.

Naturally,

the

example

above

would

also

hold

if

the

%O

2

in

the

stack

decreased,

except

the

cycle

of

intensification

would

serve

to

push

the

burner

rich

instead

of

lean.

In

addition

to

the

cycle

of

intensification

that

is

inherent

to

many

FGR

burners,

the

mechanical

design

of

the

burner

/

boiler

influences

the

repeatability

of

the

FGR

flow.

The

repeatability

of

the

FGR

flow

has

a

large

influence

on

how

well

the

O

2

trim

system

can

work.

Obviously,

non

‐

repeatability

in

the

FGR

flow

will

cause

non

‐

repeatability

in

the

%O

2

read

in

the

stack

and

therefore

the

operation

of

the

O

2

trim.

Two

different

methods

of

inducing

FGR

into

a

burner

are

illustrated

and

explained

below,

and

their

behaviors

from

an

FGR

flow

repeatability

standpoint

are

discussed.

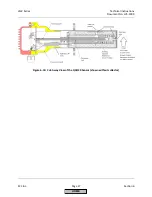

Method

shown

in

Figure

6

‐

12:

Pressure

P1

relative

to

pressure

P2

(differential

pressure

across

the

FGR

damper)

changes

drastically

with

firing

rate.

Very

little

differential

pressure

will

be

generated

across

the

FGR

damper

at

low

fire,

requiring

the

FGR

damper

to

be

mostly

open

to

achieve

even

minimal

FGR

flow

at

low

fire.

As

firing

rate

increases,

P1

will

decrease

and

P2

will

increase,

yielding

much

more

differential

pressure

across

the

FGR

damper.

As

a

result,

the

FGR

damper

will

need

to

be

ramped

closed

as

the

burner

is

ramped

up

to

high

fire.

Due

to

the

much

higher

differential

pressure

at

high

fire

the

FGR

damper

might

be

oversized

for

effective

control

at

high

fire.

Other

points

to

consider:

1.

If

using

O

2

trim,

trimming

with

the

air

actuator

(set

to

"air

influenced")

closed

should

serve

to

decrease

P1

and

decrease

the

FGR

flow

slightly

(depending

on

the

position

of

the

stack

damper).

2.

At

low

fire

when

the

FGR

valve

is

mostly

open,

even

small

changes

in

the

differential

pressure

across

the

FGR

damper

will

cause

large

changes

in

FGR

flow.

HOME

Содержание LMV 5 Series

Страница 2: ...Intentionally Left Blank ...

Страница 25: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 1 Intentionally Left Blank HOME ...

Страница 27: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 23 Section 1 Intentionally Left Blank HOME ...

Страница 41: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 7 Section 2 HOME ...

Страница 42: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 8 SCC Inc HOME ...

Страница 43: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 9 Section 2 HOME ...

Страница 44: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 10 SCC Inc HOME ...

Страница 45: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 11 Section 2 HOME ...

Страница 46: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 12 SCC Inc HOME ...

Страница 47: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 13 Section 2 HOME ...

Страница 48: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 14 SCC Inc HOME ...

Страница 49: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 15 Section 2 HOME ...

Страница 50: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 16 SCC Inc HOME ...

Страница 51: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 17 Section 2 HOME ...

Страница 52: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 18 SCC Inc HOME ...

Страница 53: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 19 Section 2 HOME ...

Страница 54: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 20 SCC Inc HOME ...

Страница 55: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 2 HOME ...

Страница 56: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 22 SCC Inc Intentionally Left Blank HOME ...

Страница 116: ...Technical Instructions LMV Series Document No LV5 1000 Section 3 Page 58 SCC Inc Intentionally Left Blank HOME ...

Страница 150: ...Technical Instructions LMV Series Document No LV5 1000 Section 4 Page 32 SCC Inc Intentionally Left Blank HOME ...

Страница 170: ...Technical Instructions LMV Series Document No LV5 1000 Section 5 Page 18 SCC Inc Intentionally Left Blank HOME ...

Страница 290: ...Technical Instructions LMV Series Document No LV5 1000 Section 8 Page 20 SCC Inc Intentionally Left Blank HOME ...

Страница 306: ...Technical Instructions LMV Series Document No LV5 1000 Section 9 Page 14 SCC Inc Intentionally Left Blank HOME ...

Страница 373: ...Intentionally Left Blank ...