36 / 60

Siemens

Actuators SAS.., SAT.. for valves

CE1P4041en

Smart Infrastructure

Functions

and control

2019-04-09

4.2.7

Forced control Z

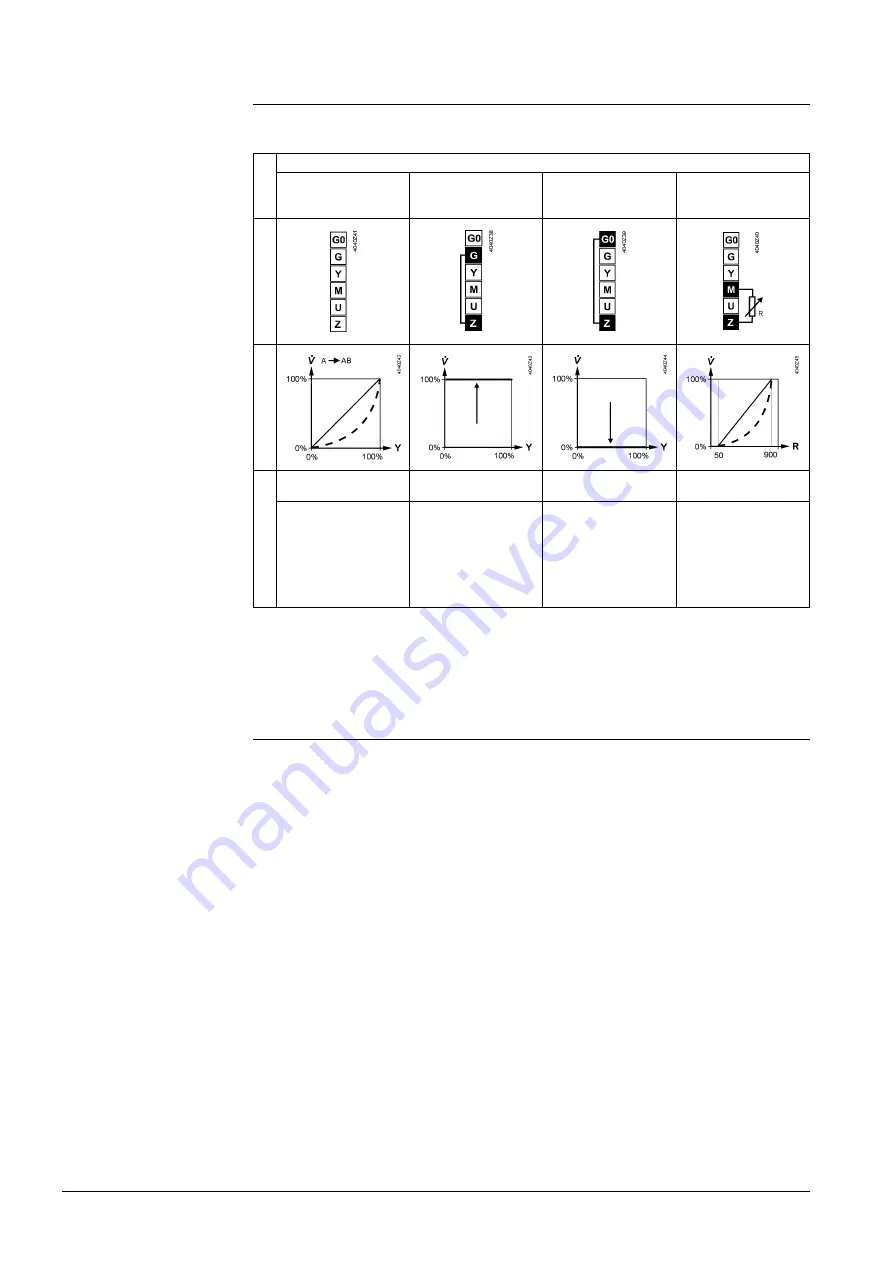

Forced control uses the following operating modes:

Z mode

No function

Fully open

Fully closed

Overriding

positioning signal “Y“

by 0…1000

Ω

Conn

ec

tion

s

T

ran

s

mi

s

si

on

Equal-percentage or

linear characteristic

Equal-percentage or

linear characteristic

Contact “Z“ not

connected,

valve follows

positioning signal ”Y”

Contact “Z“ is

connected directly to

“G“,

positiong signal ”Y”

has no impact

Contact “Z“ is

connected directly to

“G0“,

positiong signal ”Y” has

no impact

Contact “Z“ is

connected to “M“ via

resistor “R“,

starting point at 50

Ω

,

end point at 900

Ω

,

positioning signal ”Y”

has no impact

4.3

Communicating actuators Modbus RTU

4.3.1

Detection of valve seat

The actuators feature force-dependent valve seat detection. After calibration, the

exact valve stroke is filed in the actuator’s memory.

If no force is built up in the calculated end position (e.g. in the event of temperature

effects for instance), the actuator continues to operate at a reduced positioning

speed until the nominal positioning force is restored. This ensures that the valve

always fully closes.

After a power failure, valve seat identification is not active – the actuators without

fail safe function define their stroke position upon return of power at 50%. And sets

its internal setpoint in register 1 to 0%. The actuator closes at this setting. There is

a short-term deviation between the setpoint and the internal stroke position that

results in an error message in register 769 “Mechanical error, device blocked”. The

error message disappears after just a few seconds.

When the valve plug reaches its seat for the first time, the actuator readjusts its

stroke mode.

Setpoint prior to power outage 35%, no manual adjustment during the power

outage. Internal stroke position value after return of power 50%. Internal setpoint

after return of power 0%. There is an error message for a brief time prior to the

actuator moving since the setpoint of 0% is not equal to the position feedback of

SAS..

Example