s

________________________________________________________________________________

Siemens Energy & Automation, Inc. 3333 Old Milton Parkway Alpharetta, GA 30202

24

Symptom LCD

Indication Problem

Solution

The Overload

setting is set too

low.

Check the fault currents, Run Status and

Run Time; accessible in the Fault Menu

or with a computer or PDA using the

required interface.

For Inside Delta applications, displayed

fault currents should be multiplied by

1.73 to get an approximate line value.

Verify the fault occurred during the

“Maintain Current Limit”, “Ramp to

450%” or “Maintain 450%”.

Verify the starting current limit is set to

at least 200% of the motor FLA.

If the overload fault is occurring during

the “maintain 450%” and the run time is

several seconds, there may be a

mechanical issue preventing the motor

from coming up to speed.

Verify that there is some type of

viscosity control, either heaters or re-

circulation. If this is not the case,

contact technical support for assistance

on configuring the “Instantaneous Stall

Protection”.

Motor trips out on

an Overload fault

after coming up to

speed.

LCD indicates

The Starter has

detected an

Overload

condition while up

to Voltage

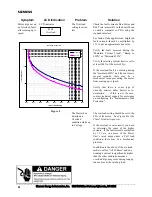

The overload setting should be set to the

FLA of the motor. See Figure 8 for the

Class 72 starter trip curves.

If the overload is set correctly you need

to determine the cause of the higher

currents. If the fault currents multiplied

by 1.73 are in excess of the Power

Unit’s rated amps under a Full load

condition, there may be a mechanical

problem.

In addition to the above, if the overload

mode is set for “All 3 Phases” and one

winding’s current is significantly higher

than the other windings, nuisance

overload trips may occur during long up

runs near or at the rated up load.

Fault

Overload

Overload Trip Tim e

1

10

100

1000

100%

150%

200%

250%

300%

350%

400%

450%

500%

I, % Overload Setting

T

im

e

(

S

eco

n

d

s)

Cold Trip

Hot Trip

Figure 8