5

COMMISSIONING AND CONFIGURATION

18

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

8022483/108R/2018-07-09 | SICK

Subject to change without notice

5

Commissioning and configuration

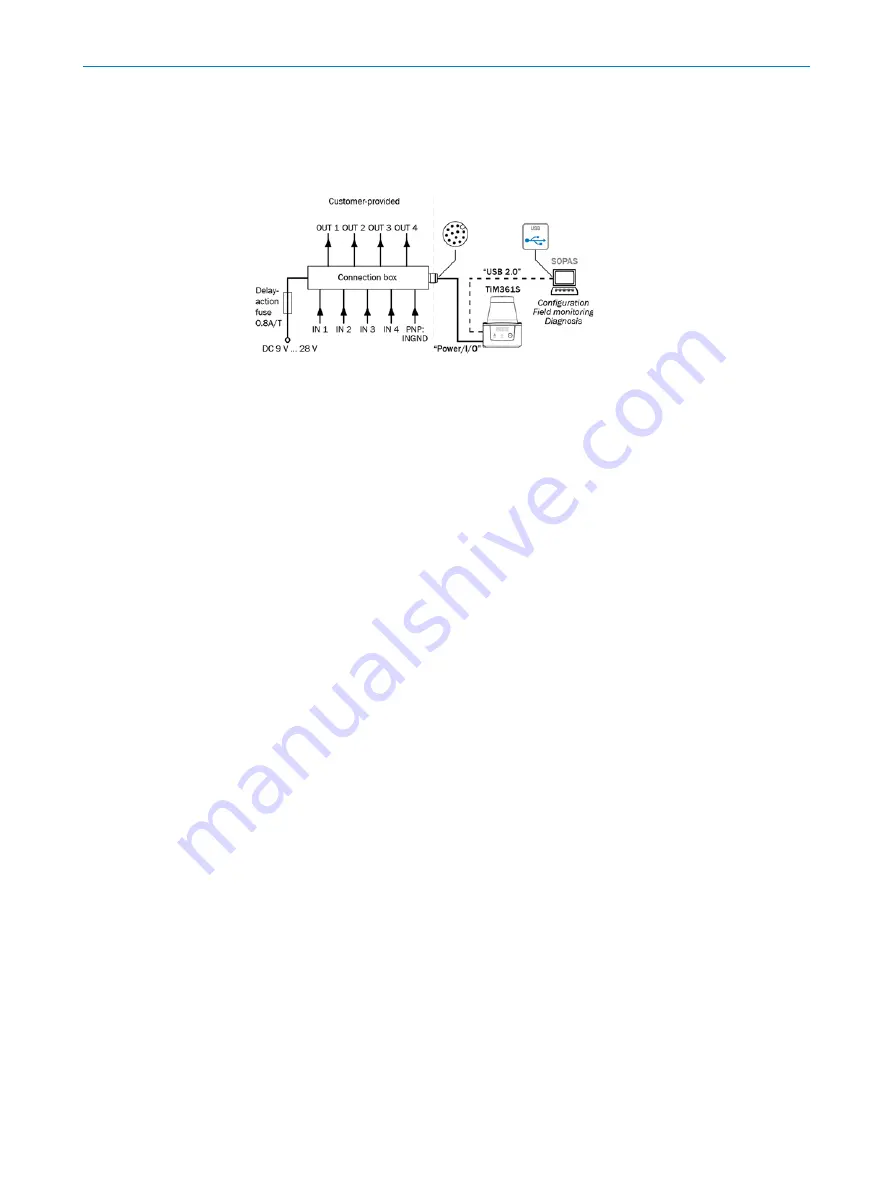

Electrical block diagram for commissioning:

TiM361S-2134101

5.1

Notes on the electrical installation

Requirements for the IP 65/IP 67 enclosure rating: the black rubber plate (USB

female connector) must be flush-mounted on the housing.

Protect the TiM361S against moisture and dust when the cover to the USB female

connector is open.

Electrical connections between the sensor and other devices may only be made or

separated in a voltage-free state. Otherwise, the devices may be damaged.

Wire cross-sections in the supply cable from the customer’s power system should

be chosen in accordance with the applicable standards.

All electrical circuits connected to the sensor must be configured as SELV or PELV

circuits (SELV = Safety Extra Low Voltage, PELV = Protective Extra Low Voltage).

The supply voltage of the TiM361S must be secured accordingly.

Only switch on the supply voltage to the sensor when the connection tasks have

been completed and the wiring has been thoroughly checked.

5.2

Prerequisites for safe electrical operation

The sensor is designed and tested for electrical safety in accordance with

IEC 61010-1:2010-06.

It is connected to the peripheral devices (voltage supply, control, actuators) via

shielded cables. The cable shield – for the supply cable, for example – rests against

the metal housing of the TiM361S. The device can either be grounded through the

cable shield or through both fastening latches.

If the peripheral devices have metal housings and if the cable shields also lie on their

housings, it is assumed that all devices involved in the installation have the same

ground potential.

This is achieved by complying with the following conditions, among others:

Mounting the devices on conductive metal surfaces

Correct grounding of the devices/metal surfaces in the system

Low-impedance and current-carrying equipotential bonding between areas with

different ground potentials, if necessary.

If these conditions are not met, e.g., on devices in a widely distributed system over

several buildings, potential equalization currents may, due to different ground

potentials, flow along the cable shields between the devices and create hazards or

malfunctions.