safety outputs switch to the OFF state. In Safety Designer, you can define the

tolerance band around the reference contour in both directions (near and far).

°

For high availability, setting both the positive tolerance band (far) and the

negative tolerance band (near) to the TZ value is recommended. (TZ = toler‐

ance range of the safety laser scanner,

°

The tolerance band must not be too wide. The reference contour field must

detect a deviation from the reference contour before access to the hazardous

point occurs next to the protective field. Deviations may occur due to changes

in position or orientation.

°

If the reference contour represents the edge of the protected opening, the

sum of the negative and positive tolerance bands must not be greater than

the resolution of the protective field.

°

If the reference contour does not represent the edge of the protected open‐

ing, the sum of the negative and positive tolerance bands must not be

greater than the projection.

•

You can define a number of contours in the reference contour field and therefore

monitor various areas in the environment.

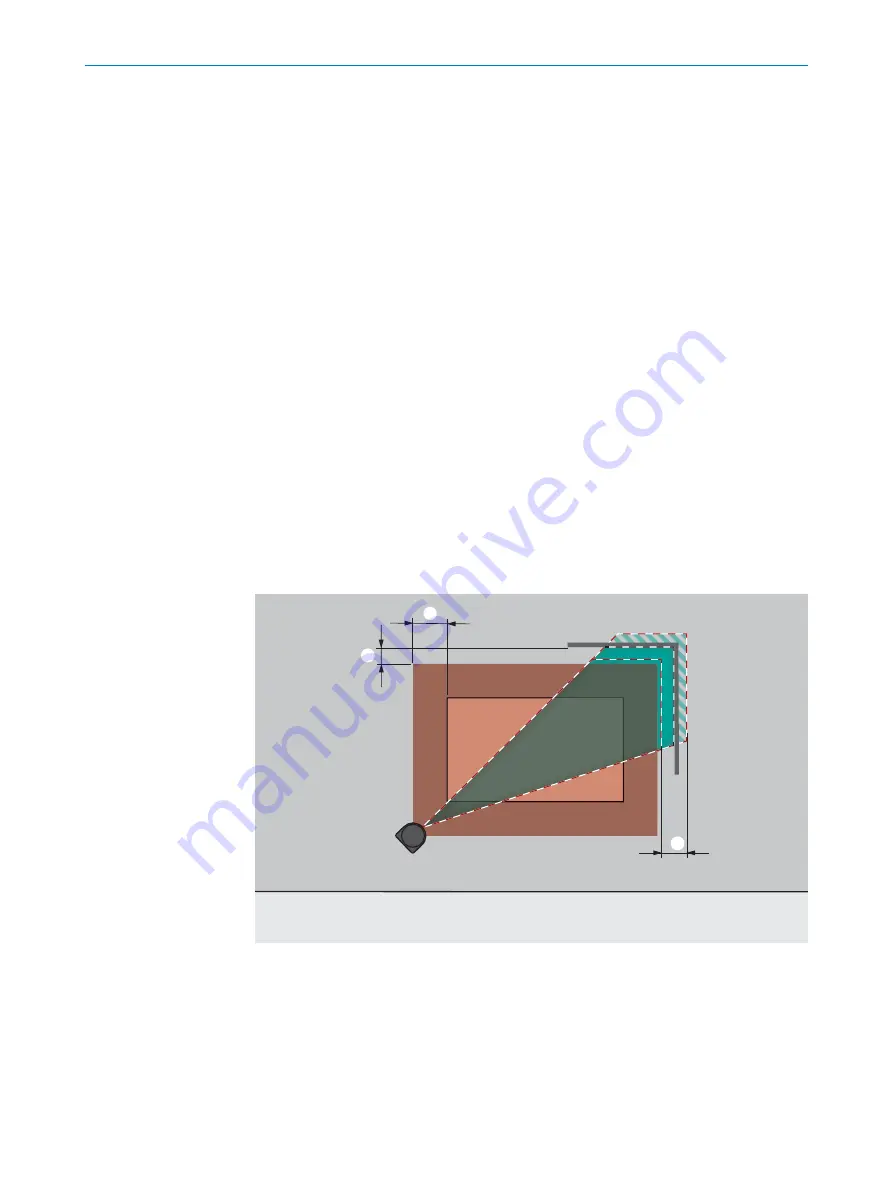

Protective field and reference contour field for hazardous point protection

The protective field must be larger than the protected opening. The required overrun (o)

is calculated using the following formula:

o ≥ (2 × TZ) – d

Where:

•

o = overrun of the protective field over the opening

•

TZ = tolerance zone of the safety laser scanner,

•

d = set resolution

3

1

2

Figure 23: Overrun of the protective field in front of an opening

1

Tolerance band of the reference contour field

2

Distance of the protective field from the contour, to ensure availability

3

o = overrun of the protective field over the opening

PROJECT PLANNING

4

8025424/1ELL/2022-01-21 | SICK

O P E R A T I N G I N S T R U C T I O N S | microScan3 Pro I/O

31

Subject to change without notice