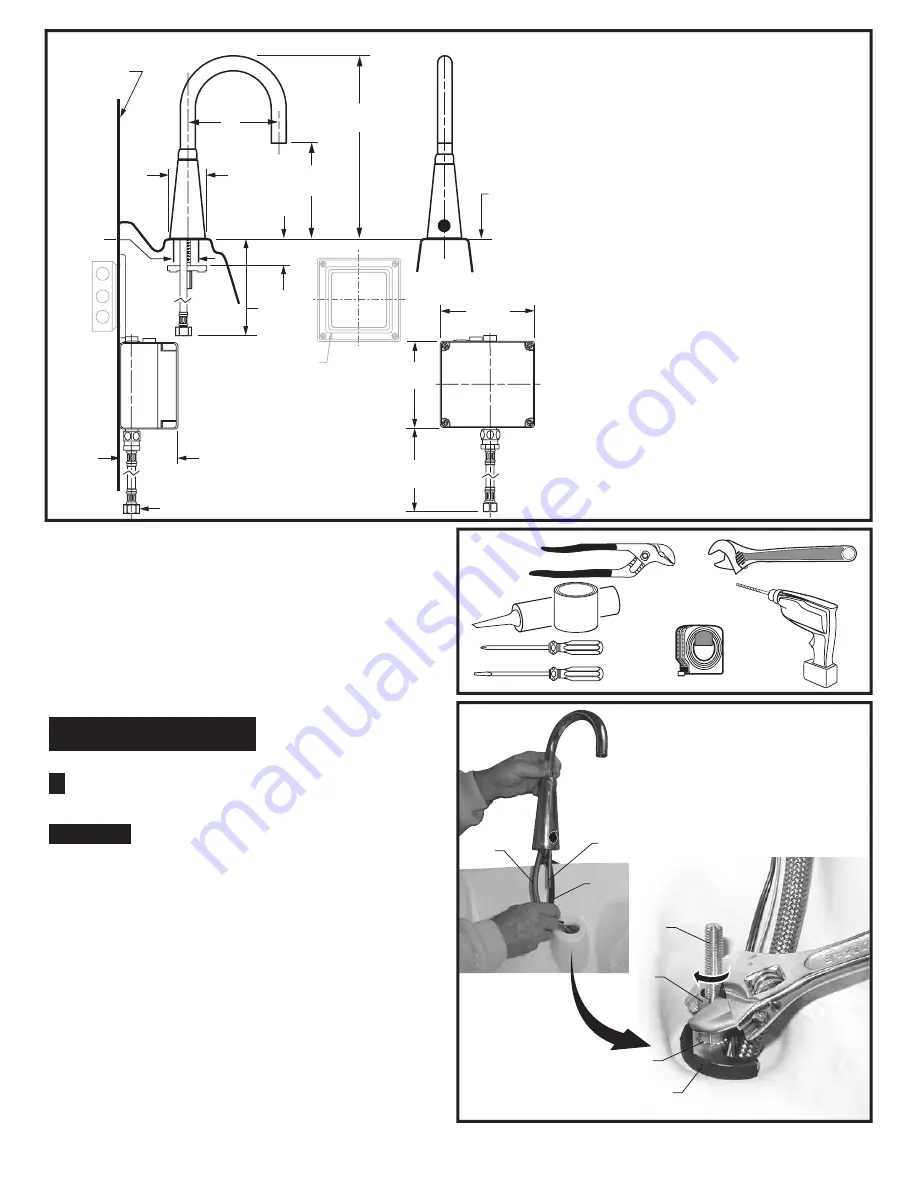

RECOMMENDED TOOLS

1

Channel Locks

2

Adjustable Wrench

3

Plumbers' Putty or Caulking

4

Phillips Screwdriver

5

Flat Blade Screwdriver

6

Electric Drill & 1/4" Drill Bit

7

Tape Measure

1

2

3

4

5

6

7

INSTALL SPOUT ASSEMBLY;

Fig. 1

INSTALLATION

CAUTION

Turn off hot and cold water

supplies before beginning

10'

1

114mm

(4-1/2)

500mm

(20")

413mm

(16-1/4)

FINISHED

WALL

32mm

(1-1/4) DIA.

125mm

(4-7/8)

60mm

(2-3/8) MAX.

MOUNTING

SURFACE

(243mm)

9-9/16"

(127mm)

5"

(133mm)

5-1/4"

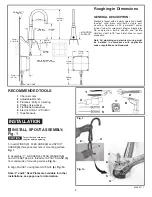

Roughing-in Dimensions

GENERAL DESCRIPTION:

Electronic faucet with proximity operation. Vandal

resistant solid brass construction single post

mounting. Operates on AC permanent power.

In-line strainer for solenoid is integral. Single inlet

3/8 compression, built-in checks, and flexible

stainless steel 16-1/4" reach inlet hose for spout

connection.

Note: All plumbing and electrical wiring must

be installed in accordance with applicable

codes, regulations and standards.

1.

Insert WIRES

(1)

, FLEX HOSE

(2)

and SPOUT

SHANK

(3)

through center hole of mounting surface.

Fig. 1.

2.

Assemble "C" WASHER

(4)

, STAR WASHER

(5)

and LOCKNUT

(6)

onto threads of SPOUT SHANK

(3)

from underside of mounting surface.

Fig. 1a.

3.

Align FAUCET and tighten LOCKNUT

(6)

.

Fig. 1a.

Note: 4" and 8" Deck Plates are available for other

installations, see page one for information.

Fig. 1a

Fig. 1

2

M 9 6 5 2 7 1

1

2

3

4

5

6

3

3/8" COMP.

81mm

(3-3/16)

(53mm)

2-1/8" DIA.

ELECTRICAL BOX OR

EQUIVALENT BY OTHERS