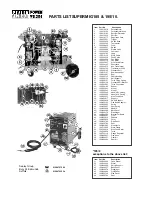

WIRING DIAGRAM FOR SUPERMIG MODELS185, & 195/9.

Origin Date: 11/6/96

Issue Date: 11/6/96

Version No: 2

Modified Date: 18/09/00

TORCH PART Nos

Item Part No Description

T1 722423

Conical Nozzle

T2

722415

Contact Tip D.0.6

T3

722416

Contact Tip D.0.8

T4

722319

Nozzle Spring

T5

722326

Diffuser Insulation

T6

722823

Swan Neck Insulation

T7

722822

Swan Neck Diffuser

T8

722819

Gun Plug Housing

T9

722665

Complete Handle

T10

722007

Ring Nut

T11

722013

Liner Nut

T12

722441

Gun Plug Body

T13

722671

Wire Guide Hose

----

722838

Complete Torch