Made in Vietnam.

Kit features.

•

Ready-made—minimal assembly & finishing required.

•

Ready-covered covering.

•

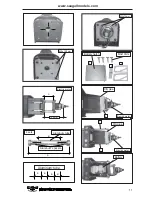

Photo-illustrated step-by-step Assembly Manual.

Specifications

Wing span------------------------------------ 65 in --------------------------------- 165cm.

Wing area------------------------------------782.8 sq.in ------------------- 50.5 sq.dm.

Approximate flying weight---------------- 9.7lbs -------------------------------- 4.4kg.

Length ---------------------------------------- 58.8 in -----------------------------149.4cm.

Recommended engine size------------ .75 - .91 cu.in ------------------- 2-stroke.

.1.00 - 1.14 cu.in ---------------- 4-stroke.

ELECTRIC CONVERSION : OPTIONAL.

Radio System required 4 channels with 6 servos.

Flying skill level Intermediate/advanced.

“Graphics and specifications may change without notice”.

ASSEMBLY MANUAL

MS: SEA 91

CAP 232