Section 01 MAINTENANCE

Subsection 03 (STORAGE PROCEDURES)

CAUTION:

Never run engine without supplying

water to the exhaust cooling system when wa-

tercraft is out of water.

CAUTION:

Never run engine longer than 5 min-

utes. Drive line seal has no cooling when wa-

tercraft is out of water.

Run the engine about 20 seconds at a fast idle

between 4000 - 5000 RPM.

Ensure water flows out of jet pump while flushing.

Close the water tap, then stop the engine.

CAUTION:

Always close the water tap before

stopping the engine.

Unlock and remove coupler hose. Reinstall dust

cap over flushing connector.

Remove hose pincher from water outlet hose.

CAUTION:

Serious damage to exhaust system

can occur if hose pincher is not removed.

CLOSED LOOP COOLING

SYSTEM (ENGINE)

Antifreeze should be replaced for the storage pe-

riod to prevent antifreeze deterioration.

Make sure to perform an antifreeze density test.

For the coolant replacement procedure, refer to

COOLING SYSTEM section.

CAUTION:

Improper antifreeze mixture might

allow freezing of the liquid in the cooling sys-

tem if vehicle is stored in area where freezing

point is reached. This would seriously damage

the engine. Failure to replace the antifreeze

for storage may allow its degradation that

could result in poor cooling when engine will

be used.

ENGINE LUBRICATION

Engine must be lubricated to prevent corrosion on

internal parts.

Fogging of the engine is recommended at the end

of the season and before any extended storage

period to provide additional corrosion protection.

This will lubricate the engine intake valves, the

cylinders and the exhaust valves.

To fog the engine, proceed as follows:

– Remove the two bolts that hold the fuel rail on.

– Remove the rail along with the three fuel injec-

tors.

– Spray liberally BOMBARDIER LUBE lubricant

(P/N 293 600 016) into the intake ports.

– Crank engine several times while keeping throt-

tle fully depressed (drown engine mode) to dis-

tribute lubricant in cylinders, on intake valves

and exhaust valves.

– Carefully inspect O-rings condition before re-

installing fuel injectors. Replace O-rings with

new ones if damaged. Lubricate O-rings with

injection oil prior to installing.

– Reinstall the injectors.

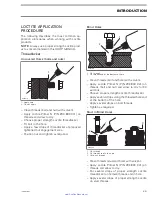

– Apply Loctite 243 (blue) (P/N 293 800 060) and

torque the two bolts to 9 N•m (80 lbf•

in

) that

hold the fuel rail on.

– Make sure there is no leak at injectors when

cranking the engine in the upcoming steps.

WARNING

If a leak is present, immediately stop the en-

gine. Do not start engine until the leak is re-

paired.

WARNING

At preseason preparation, ensure to perform

a fuel pressure test and ensure there is no

leak. Also run engine and check for leaks.

Refer to FUEL TANK AND FUEL PUMP sec-

tion.

THROTTLE BODY LUBRICATION

It is recommended to lubricate the throttle body

to prevent corrosion on external and internal parts

especially if the craft is used in salt water.

Remove the air intake hose from throttle body.

Open the throttle body valve by pressing slightly

the throttle lever and spray BOMBARDIER LUBE

lubricant (P/N 293 600 016) through the throttle

body bore to lubricate valve mechanism. Then

spray generously the external parts of throttle

body.

Install air intake hose.

ANTIFREEZING PROTECTION

Supercharged Intercooled Models

The exhaust system is self draining, but the inter-

cooler and manifold need the following protection.

– Remove both intercooler hoses.

8

smr2005-004

www.SeaDooManuals.net