2. Always break in the blade before you start normal cutting.

3. Do not apply excessive down pressure on the workpiece. Excessive down pressure will cause the teeth

to remove too large of a chip, resulting in premature dulling or breakage.

4. Use a good quality, synthetic coolant and maintain the proper ratio of coolant to water as

recommended in SECTION 4.7.

5. Have your blades re-sharpened by someone who has the right equipment for circular cold saw blades.

Improper re-sharpening is one of the most common problems encountered in cold sawing.

6. Keep the blade flange, the face of the blade spindle and the blade clean and free from nicks. Any

contamination or nicks on the flange, spindle or the blade will cause the blade to run out of alignment.

7. Always remove the back lash when installing a blade. For instructions, REFER TO SECTION 6.1.

Also, check the condition of the drive pins when replacing the blade. If the drive pins are broken or

worn, replace them.

8. Any of the above problems may cause a condition known as pick-up. Pick-up is caused when small

pieces of the material being cut adhere themselves to the blade. When pick-up is present, you will feel

a jerking or jumping motion in the saw head while cutting. This is caused by the blade being pinched

as it goes through the material where the pick-up is present. Pick-up can be removed by using a fine

honing stone or a very fine file. When removing pick-up, care must be taken not to remove any part

of the blade. After the pick-up has been removed, review the above items to determine what caused

the problem.

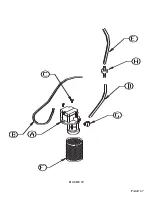

8.3 COOLANT SYSTEM

1. IF COOLANT WILL NOT FLOW:

A. Check the wiring connections to the pump and make sure that the pump is running.

B. Check the level of the coolant in the reservoir. If the level is less than 3 inches, the fluid will not flow.

C. Check the reservoir for contamination or sludge build-up that may be blocking the pump inlet.

D. Remove the coolant line from the guard and make sure that it’s clear. Also, make sure that the valve

on the guard is open.

2. IF THE COOLANT PUMP IS LEAKING:

A. Check the connections on the coolant lines.

B. If the pump itself is leaking, there is a seal kit available. For instructions, SEE SECTION 5.4. For

part numbers, SEE SECTION 9.6.

PAGE 53

Содержание CPO 350

Страница 1: ...CPO 350 VARIABLE SPEED COLD SAW PRINTED SEPTEMBER 2014...

Страница 7: ...PAGE 7 FIGURE 1...

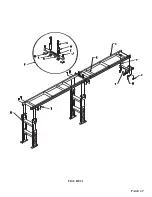

Страница 8: ...4 2 MACHINE MOVING PROCEDURES SEE FIGURE 2 BELOW PAGE 8 FIGURE 2...

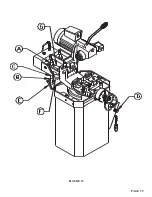

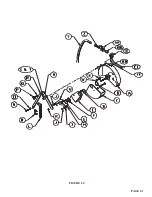

Страница 11: ...PAGE 11 350 VS POWER DOWN 230 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 1...

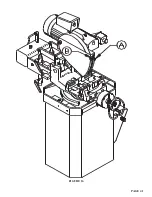

Страница 12: ...PAGE 12 350 VS MANUAL PK 230 VOLT FIGURE 3 2...

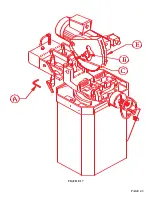

Страница 13: ...PAGE 13 350 VS POWER DOWN 460 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 3...

Страница 14: ...PAGE 14 350 VS MANUAL PK 460 VOLT FIGURE 3 4...

Страница 17: ...PAGE 17 FIGURE 4...

Страница 19: ...PAGE 19 FIGURE 5...

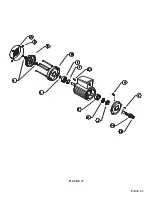

Страница 27: ...PAGE 27 FIGURE 8 FIGURE 9...

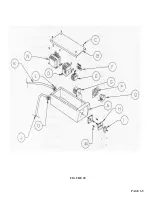

Страница 29: ...PAGE 29 FIGURE 10...

Страница 33: ...PAGE 33 FIGURE 12...

Страница 35: ...PAGE 35 FIGURE 13...

Страница 37: ...PAGE 37 FIGURE 14...

Страница 39: ...PAGE 39 FIGURE 15...

Страница 41: ...PAGE 41 FIGURE 16...

Страница 43: ...PAGE 43 FIGURE 17...

Страница 45: ...7 2F POWER DOWN FEED WIRING DIAGRAM Ser s 6425 Up PAGE 45 FIGURE 19...

Страница 46: ...7 2G PNEUMATIC SCHEMATIC POWER DOWN MACHINES PAGE 46 FIGURE 20...

Страница 47: ...THIS PAGE LEFT BLANK INTENTIONALLY PAGE 47...

Страница 49: ...PAGE 49 FIGURE 21...

Страница 51: ...PAGE 51 FIGURE 22...

Страница 55: ...PAGE 55 FIGURE 23...

Страница 59: ...PAGE 59 FIGURE 25...

Страница 61: ...PAGE 61 FIGURE 26...

Страница 63: ...PAGE 63 FIGURE 27...

Страница 65: ...PAGE 65 FIGURE 28...

Страница 67: ...PAGE 67 FIGURE 29...

Страница 69: ...PAGE 69 FIGURE 30...

Страница 71: ...PAGE 71 FIGURE 31...

Страница 73: ...PAGE 73 FIGURE 32...

Страница 75: ...PAGE 75 FIGURE 33...

Страница 77: ...PAGE 77 FIGURE 33...

Страница 79: ...PAGE 79 FIGURE 34...

Страница 81: ...PAGE 81 FIGURE 35...

Страница 83: ...PAGE 83 FIGURE 36...

Страница 85: ...PAGE 85 FIGURE 37...

Страница 87: ...PAGE 87 FIGURE 38...

Страница 89: ...PAGE 89 FIGURE 39...

Страница 91: ...PAGE 91 FIGURE 40...

Страница 93: ...PAGE 93 FIGURE 41...