4.7 COOLANT SYSTEM

The coolant reservoir has a capacity of ten (10) gallons (37.8 liters). One gallon of coolant is shipped with

the saw. For normal cutting, it should be mixed in a ratio of one part coolant to seven parts water. In

conditions of heavier cutting, the ratio of water should be reduced to five parts. We recommend using

only pure, synthetic, water soluble cutting oils. Petroleum based cutting oils will reduce the life of the

coolant pump considerably. We recommend pre-mixing the coolant before adding it to the saw.

When cutting alloy steels such as stainless steel, we recommend a special mix coolant designed for these

applications. For additional information on available coolants, SEE SECTION 10.6.

5.0 MAINTENANCE AND LUBRICATION

5.1 LUBRICATION

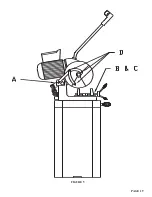

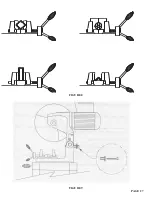

SEE FIGURE 5 ON THE FOLLOWING PAGE.

Before operating the saw, grease the pivot pins (A) and apply penetrating oil to the vise spindle and

guides (B and C). Once a week, grease all of the pivot pins and oil all of the rivet connections on the

guard linkage. Check the level of the fluid in the saw head checking the sight glass in the front of the head

casting. To add fluid, remove the breather plug next to the draw handle. On machines not equipped

with a breather, you have to remove the draw handle and add gear lubricant through this opening.

Clean the chips out of the vise every day and apply penetrating oil to the spindle and guide pins. Clear the

chips with a brush or similar device. DO NOT use compressed air. For additional information if your saw

is equipped with a power vise or power down feed option, SEE SECTIONS 7.1 THRU 7.2.

PAGE 18

Содержание CPO 350

Страница 1: ...CPO 350 VARIABLE SPEED COLD SAW PRINTED SEPTEMBER 2014...

Страница 7: ...PAGE 7 FIGURE 1...

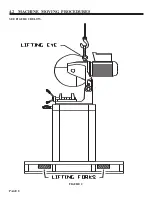

Страница 8: ...4 2 MACHINE MOVING PROCEDURES SEE FIGURE 2 BELOW PAGE 8 FIGURE 2...

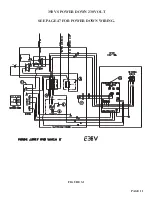

Страница 11: ...PAGE 11 350 VS POWER DOWN 230 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 1...

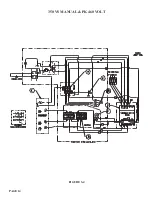

Страница 12: ...PAGE 12 350 VS MANUAL PK 230 VOLT FIGURE 3 2...

Страница 13: ...PAGE 13 350 VS POWER DOWN 460 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 3...

Страница 14: ...PAGE 14 350 VS MANUAL PK 460 VOLT FIGURE 3 4...

Страница 17: ...PAGE 17 FIGURE 4...

Страница 19: ...PAGE 19 FIGURE 5...

Страница 27: ...PAGE 27 FIGURE 8 FIGURE 9...

Страница 29: ...PAGE 29 FIGURE 10...

Страница 33: ...PAGE 33 FIGURE 12...

Страница 35: ...PAGE 35 FIGURE 13...

Страница 37: ...PAGE 37 FIGURE 14...

Страница 39: ...PAGE 39 FIGURE 15...

Страница 41: ...PAGE 41 FIGURE 16...

Страница 43: ...PAGE 43 FIGURE 17...

Страница 45: ...7 2F POWER DOWN FEED WIRING DIAGRAM Ser s 6425 Up PAGE 45 FIGURE 19...

Страница 46: ...7 2G PNEUMATIC SCHEMATIC POWER DOWN MACHINES PAGE 46 FIGURE 20...

Страница 47: ...THIS PAGE LEFT BLANK INTENTIONALLY PAGE 47...

Страница 49: ...PAGE 49 FIGURE 21...

Страница 51: ...PAGE 51 FIGURE 22...

Страница 55: ...PAGE 55 FIGURE 23...

Страница 59: ...PAGE 59 FIGURE 25...

Страница 61: ...PAGE 61 FIGURE 26...

Страница 63: ...PAGE 63 FIGURE 27...

Страница 65: ...PAGE 65 FIGURE 28...

Страница 67: ...PAGE 67 FIGURE 29...

Страница 69: ...PAGE 69 FIGURE 30...

Страница 71: ...PAGE 71 FIGURE 31...

Страница 73: ...PAGE 73 FIGURE 32...

Страница 75: ...PAGE 75 FIGURE 33...

Страница 77: ...PAGE 77 FIGURE 33...

Страница 79: ...PAGE 79 FIGURE 34...

Страница 81: ...PAGE 81 FIGURE 35...

Страница 83: ...PAGE 83 FIGURE 36...

Страница 85: ...PAGE 85 FIGURE 37...

Страница 87: ...PAGE 87 FIGURE 38...

Страница 89: ...PAGE 89 FIGURE 39...

Страница 91: ...PAGE 91 FIGURE 40...

Страница 93: ...PAGE 93 FIGURE 41...