Commissioning and maintenance

02.00|ROTA TP |en

47

Maintenance intervals

Lubrication of the grease areas:

Lubrication interval Strain

every 25 hours

normal / coolant utilization

every 8 hours

high / coolant utilization

after 1200 hours or

as needed

Total cleaning with disassembly of the

chuck, depending on type and degree of

contamination

Hardened Reversible Jaws and Soft Top Jaws

Make sure that the top jaws are set for clamping on the fine serration

so that no more than 2/3 of the jaw stroke has to be extended

(clamping reserve).

Hardened reverse jaws may be used only in sets as packaged at

the factory, since they are ground in sets on the chuck. Normally,

one set of hardened reverse jaws is ordered with the chuck. During

assembly and disassembly of the reverse jaws numbered 1 to 3

make sure that the single jaws are paired with the base jaws with

the same numbers in order to achieve good true running properties.

Turning of the soft top jaws must be performed on the chuck in

the same clamping position and at the same operating pressure

specified for machining of the workpiece.

Hardened roughing jaws whose clamping surfaces have conical

teeth with good grip should be used for rough turning work or

preturned workpieces.

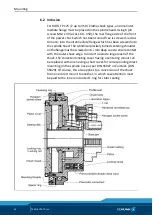

7.3

7.4