Mounting

02.00|ROTA TP |en

35

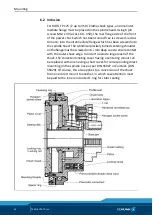

Distributor ring

The distributor ring of the front-mounted power chuck model RO-

TA TP 125 – 350 and TP-LH 315 – 350 is supplied with 2 possible

means of fastening as standard.

Distributor ring: normal fastening

The distributor ring is automatically centered with the chuck body

by a plastic centering sleeve (Hostaform C).

The following maximum speeds are possible with this mounting:

ROTA TP125-25 ROTA TP 160-38 ROTA TP 200-55 ROTA TP 250-58 ROTA TP 315-90

4000 min

-1

4000 min

-1

2800 min

-1

2200 min

-1

1800 min

-1

ROTA TP 315-105

ROTA TP 350-115

ROTA TP-LH 315-105 ROTA TP LH350-115

2200 min

-1

2200 min

-1

2200 min

-1

2200 min

-1

Two threaded holes are arranged on the circumference at less

than 120° from each other and at a distance from the pneumatic

connection so that the distributor ring can be secured against

turning by means of a set-screw belonging to the equipment. The

set-screw is screwed into the threaded hole that brings the

pneumatic connections into a suitable position so that the

pneumatic supply lines can be routed to the control unit over the

shortest possible distance. The set-screw must be able to move

back and forth freely in both directions, but no more than 3 mm,

in a fork rigidly mounted in the headstock or lathe bed. And the

fork must be produced and installed in such a way that it does

not apply pressure to the distributor ring axially or radially.

Note

Therefore, ONLY flexible connection cables may be used.

6.3

6.3.1