_________________________________________________________________________________________

schunk.com

XND.00020.002_A – 10/2018

27

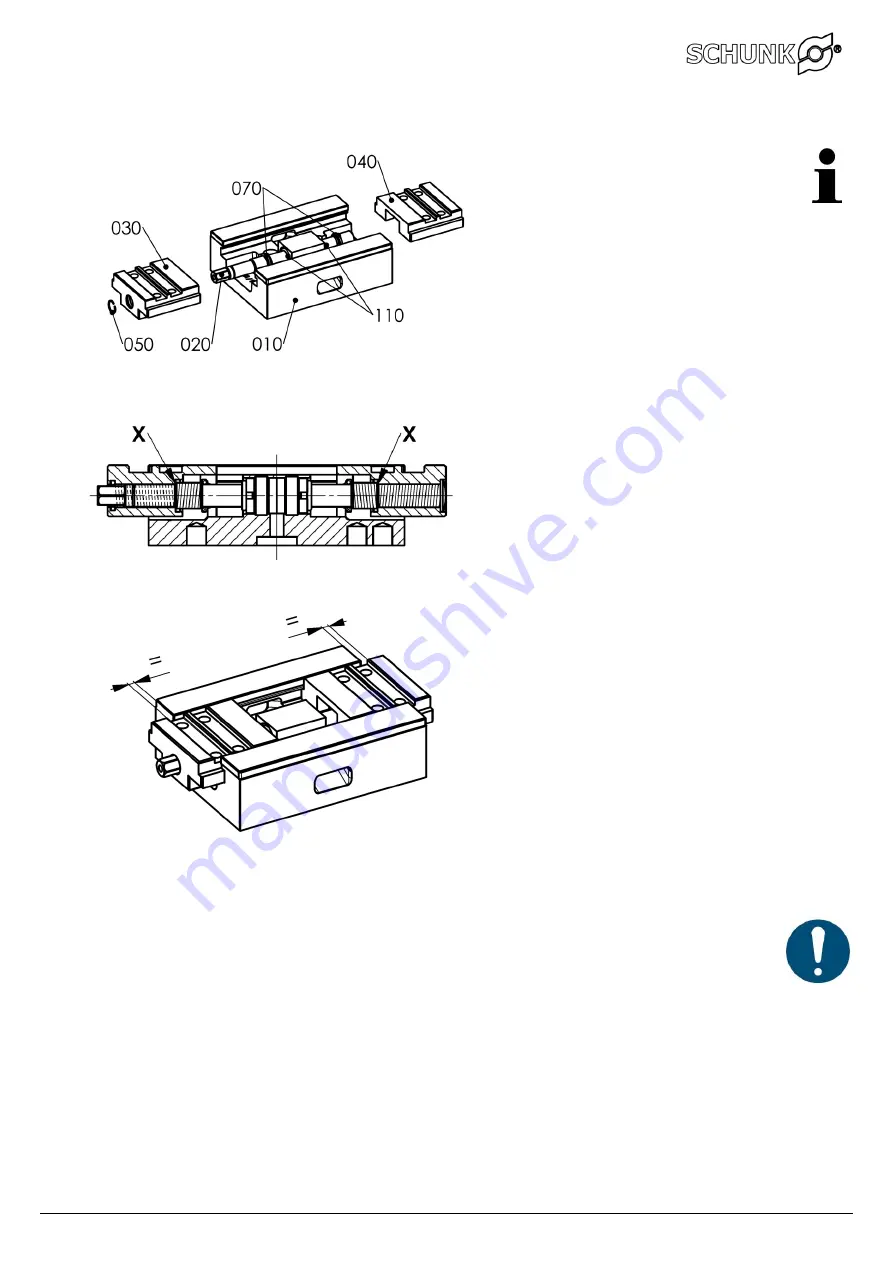

6.2

Assembly

Re-grease the thread of the spindle

and at the carriages using e.g. EP

high-performance grease, such

as LAGERMEISTER WHS 2002,

NLGI class 1-2.

Oil the running surfaces and guides of the

vice using e.g. with MOTOREX Supergliss

68 K to ISO VG 68.

Insert both carriages (pos. 030 and pos. 040)

into the tool body (pos. 010) up

to the start of the

X

of the spindle

(pos. 020).

Insert the threads by turning the spindle

to the right and pressing on both carriage

ends at the same time.

Important:

Both carriages must come

together and engage in the threads at

the same time. This is imperative in order

to ensure the consistent central position

of the system.

Checking the central position

The gap between the carriage slot and the

end face of the tool body must be identical

on both sides. If this is not the case, remove

the carriages again and repeat the process.

Finally, fully join the carriages together

so that the inside wipers (pos. 070) are

again pressed into the carriages via the

spacer O-rings (pos. 010).

Re-insert the circlip (pos. 050) into the

groove of the spindle.

Important:

The high degree of precision of the KSC is achieved using a processing step while

it is mounted. The components of different vices must not be interchanged.

This is imperative in order to ensure the consistent central position of the system

and the fitting of the guide between the slides and tool body.