10

Operating instructions

Safety-monitoring module

SRB-E-204ST / SRB-E-204PE

EN

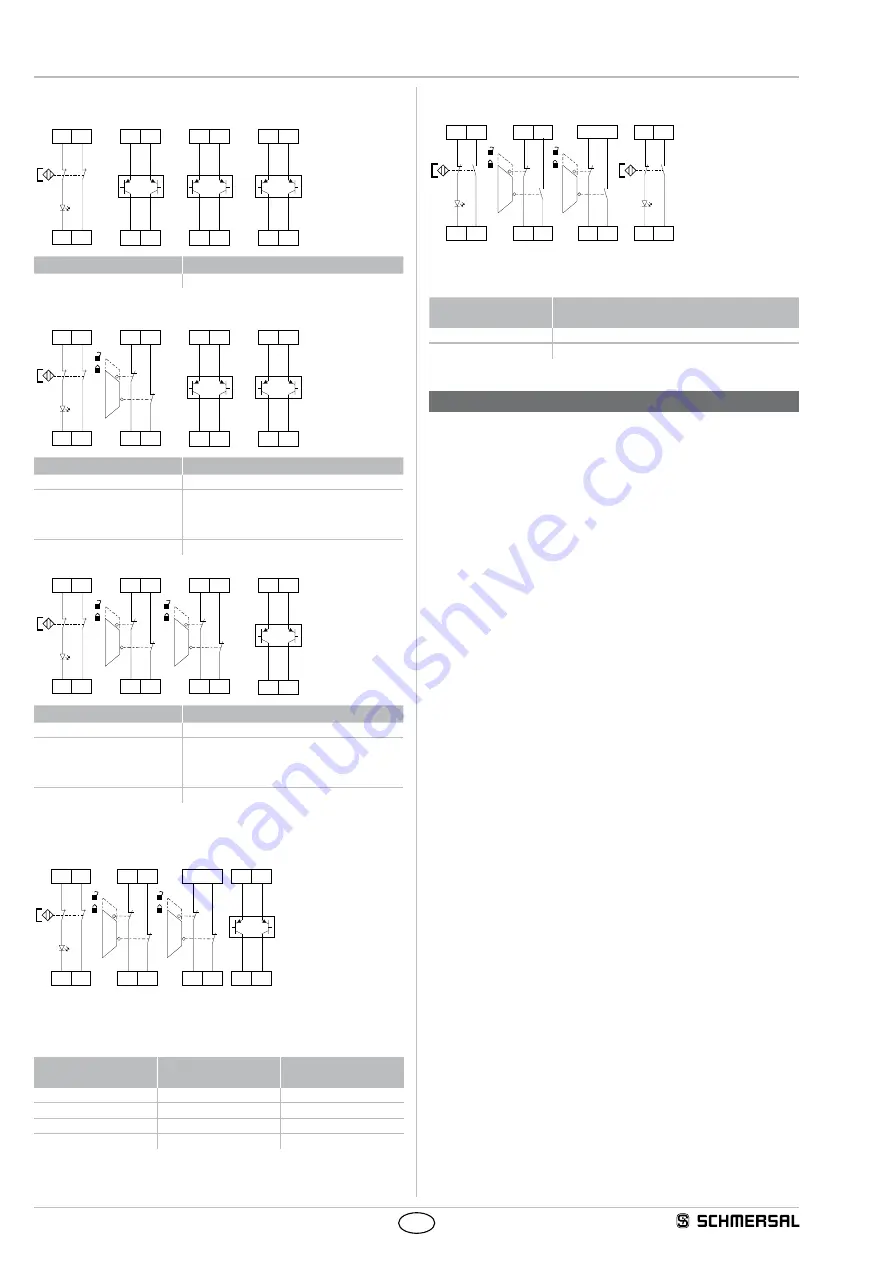

Differentiated cross-fault monitoring of sensors

(Category 4 – PL e to ISO 13849-1 possible)

S12 S22

S11 S21

S32

+24V

S42

+24V

S52

+24V

S62

+24V

S72

+24V

S82

+24V

Rotary knob position

Type / function

7

SRB-E-204PE

S12 S22

S11 S21

S32 S42

S31 S41

S52

+24V

S62

+24V

S72

+24V

S82

+24V

Rotary knob position

Type / function

8

SRB-E-204PE

11

SRB-E-204ST

Reset button with detection

of the trailing edge

12

SRB-E-204ST Autostart

S12 S22

S11 S21

S32 S42

S31 S41

S52 S62

S51 S61

S72

+24V

S82

+24V

Rotary knob position

Type / function

9

SRB-E-204PE

13

SRB-E-204ST

Reset button with detection

of the trailing edge

14

SRB-E-204ST Autostart

Without cross-wire monitoring (Sensor 1 – 4)

(Cat. 4 - PL e to ISO 13849-1 only possible with protective wiring)

S32 S42

S31 S41

S52 S62

S12 S22

S11 S21

+24

VDC

S72

+24V

S82

+24V

• Unrequired inputs S12, S22, S32, S42, S52, S62, S72, S82 must be

switched to +24VDC or bridged to outputs S11, S21, S31, S41, S51,

S61.

Rotary knob

position

Cross-wire

monitoring

Synchronisation

3

No

Yes

4

No

No

9 (SRB-E-204ST)

No

Yes

10 (SRB-E-204ST)

No

No

Dual channel signal processing NC / NO (Sensor 1 – 4)

(Category 4 – PL e to ISO 13849-1 possible)

S32 S42

S31 S41

S52 S62

S12 S22

S11 S21

+24

VDC

S72 S82

S51 S61

• Unrequired inputs S12, S32, S52, S72 must be switched to +24VDC

or bridged to outputs S11, S21, S31, S41, S51, S61.

Rotary knob

position

Function

(SRB-E-204ST)

5

Reset button (detection of the trailing edge)

6

Reset without monitoring / autostart

8. Set-up and maintenance

8.1 Commissioning

The safety relay module features protection class IP54 for installation

in a switch cabinet.

The safety relay module is delivered ready for operation.

Application 1 is preset in the factory.

8.2 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct fixing

2. Check the integrity of the cable entry and connections

3. Check the safety-monitoring module's enclosure for damage

4. Check the electrical function of the connected sensor technology

and their influence on the safety-monitoring module and the

downstream actuators

The safety relay module features self-test functions.

If a fault is detected, the system adopts a safe mode and leads,

if necessary, to undelayed deactivation of all safety outputs.

8.3 Behaviour in the case of faults

In the event of a fault the following procedure is recommended:

1. Identify faults according to flash codes from chapter 6.2.

2. Rectify the fault if it is described in the table.

3. Switch operating voltage off and on and erase fault mode.

If fault could not be rectified, please contact the manufacturer.