8

EN

SLC 420 IP 69 K

Operating instructions

Safety light curtain

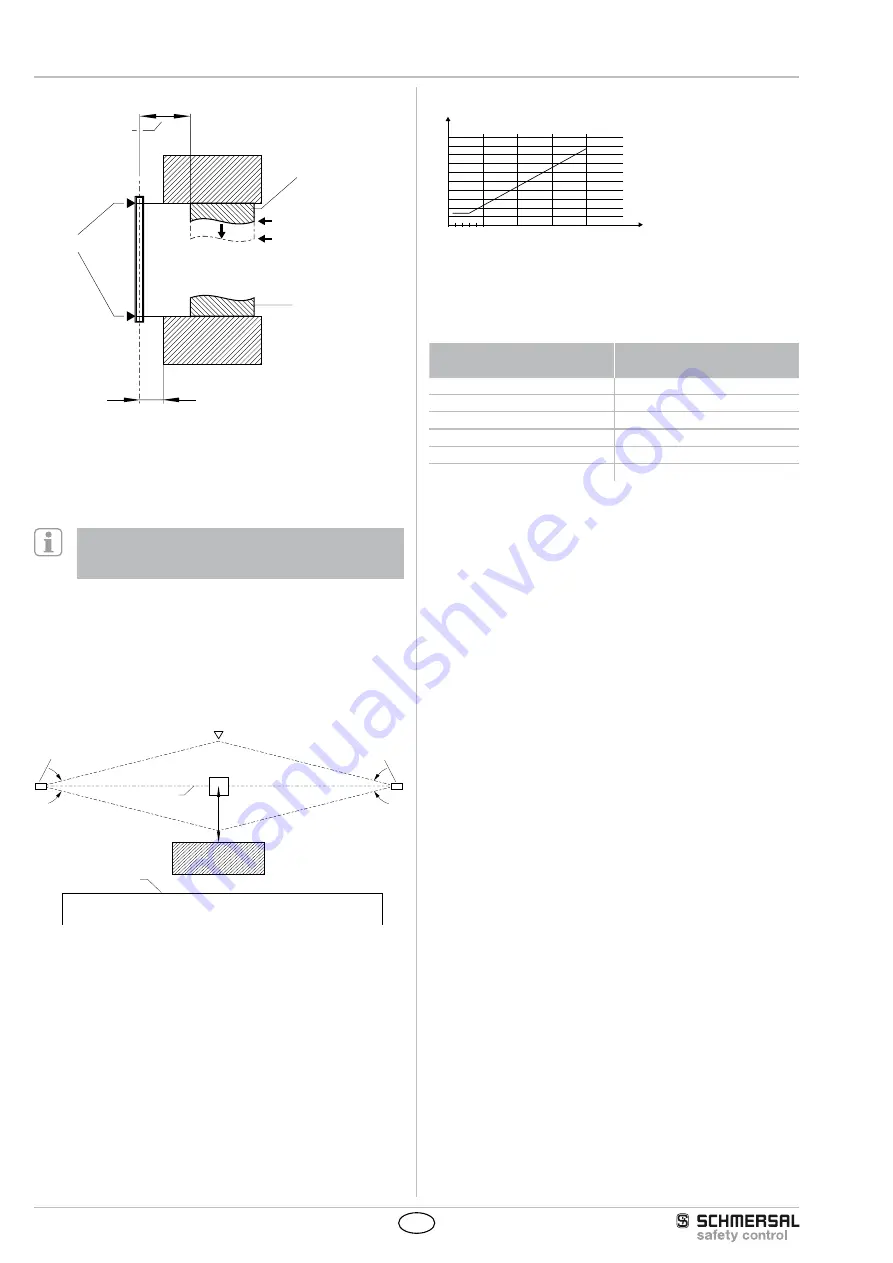

Safety distance to the hazardous area

Limit of the hazardous point

Safety distance (S)

Protection field marking

Tool - upper part

Signal to stop the

hazardous movement

Standstill of the hazardous

movement

t

n

= t

B

- t

A

Tool - lower part

t

A

S

t

B

≤

75 mm = max distance for protection against stepping over

To prevent persons from stepping over the protection field

this dimension must be imperatively respected and observed

The formulae and calculation examples are related to the vertical set-up

(refer to drawing) of the light curtain with regard to the hazardous point

Please observe the applicable harmonised EN standards and possible

applicable national regulations

The successor standards of the EN 999 for calculating the

minimum distances of the safety guards with regard to the

hazardous point are EN ISO 13855 and EN ISO 13857

3.4.1 Minimum distance to reflecting surfaces

During the installation, the effects of reflecting surfaces must be taken

into account In case of an incorrect installation, interruptions of the

protection field could possibly not be detected, which could lead to

serious injuries The hereafter-specified minimum distances with regard

to reflecting surfaces (metal walls, floors, ceilings or parts) must be

imperatively observed

8°

8°

a= 262 mm

Access direction

Receiver

Obstacle

optical axis

Transmitter

reflecting body

(eg Material container)

Limit of the hazardous

point

a=130mm

5°

5°

Safety distance a

a [mm]

D [m]

0

3 5

10

100

200

300

400

500

600

700

800

900

1000

15

20

Calculate the minimum distance to reflecting surfaces as a function of

the distance with an aperture angles of ± 25° degrees or use the value

from the table below

Distance between transmitter

and receiver [m]

Minimum distance a [mm]

02 … 30

130

4

175

5

220

7

310

10

440

15

660

Formula: a = tan 2.5° x L [mm]

a = Minimum distance to reflecting surfaces

L = Distance between transmitter and receiver