6

Operating instructions

Safety sensor

CSS 34

EN

5. Diagnostic functions

5.1 Operating principle of the diagnostic LEDs

The safety sensor indicates the operating condition and faults by means

of three-colour LEDs located in the lateral surfaces of the sensor.

The following LED indicators are the same for safety sensors

with conventional diagnostic output as for those with a serial

diagnostic function.

The green LED indicates that the safety sensor is ready for operation.

The sensor is not actuated.

The yellow LED indicates the switching condition of the safety outputs.

The flashing can be used to prematurely detect variations in the

clearance between the sensor and the actuator (e.g. sagging of a safety

guard). The sensor must be adjusted before the distance to the actuator

increases and before the safety outputs are disabled, thus stopping the

machine. If an error is detected, the red LED will be activated.

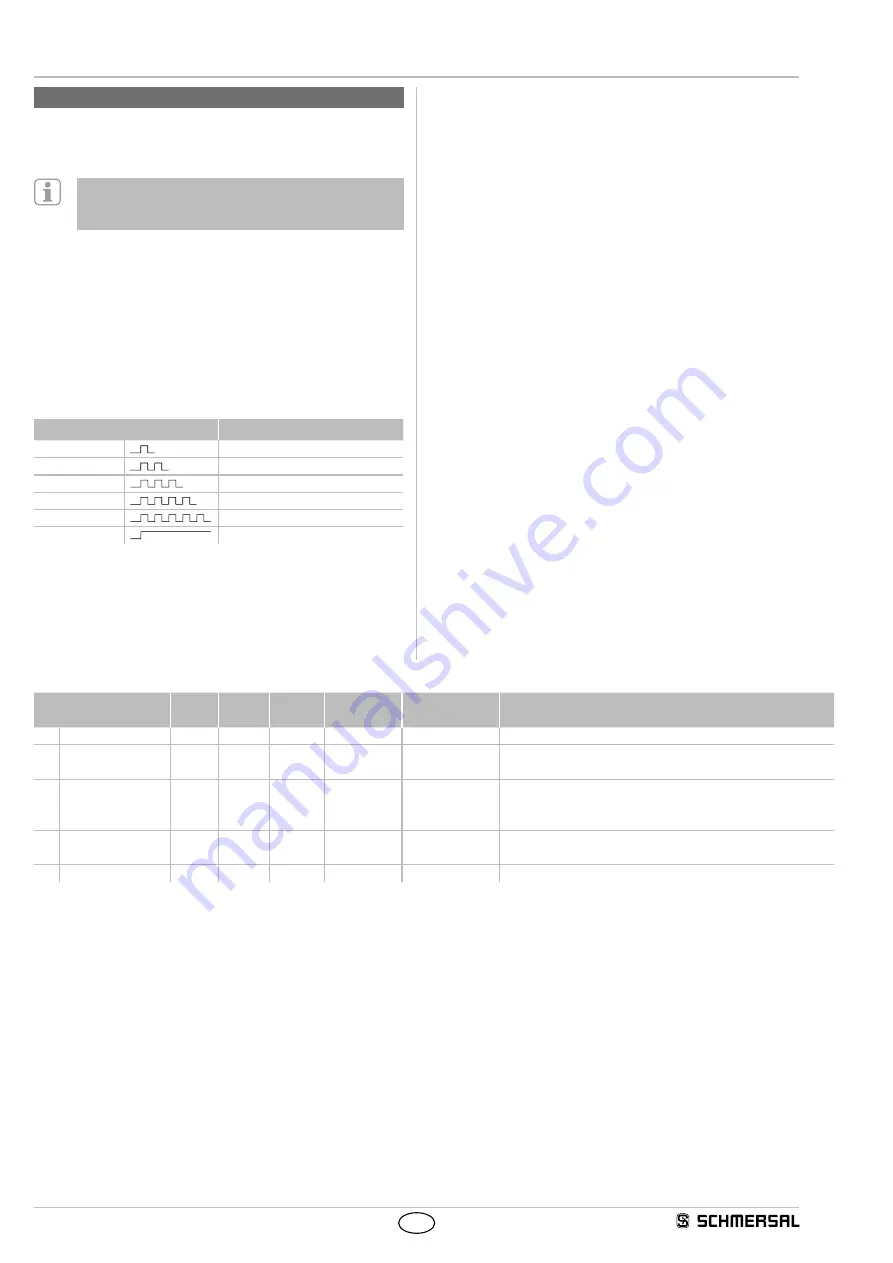

Flash codes red diagnostic LED

LED indication (red)

Error cause

1 flash pulse

Error output Y1

2 flash pulses

Error output Y2

3 flash pulses

Cross-wire Y1/Y2

4 flash pulses

ambient temperature too high

5 flash pulses

Wrong or defective actuator

Continuous red

Internal error

5.2 Operating principle of the electronic diagnostic output

Table 1: Examples of the diagnostic function of the safety-sensor with conventional diagnostic output

Sensor function

LED

green red

yellow

Diagnostic

output

Safety outputs

Y1, Y2

Note

I.

Supply voltage

On

Off

Off

0 V

0 V

Voltage on, no evaluation of the voltage quality

II. actuated

On

Off

On

24 V

24 V

The yellow LED always signals the presence of an actuator

within range

III. Actuated, actuator

in limit area

On

Off

Flashes

(1Hz)

24 V pulsed

24 V

The sensor must be adjusted before the distance to the

actuator increases and before the safety outputs are disabled,

thus stopping the machine

IV. Error warning,

sensor actuated

On

Flashes

On

0 V

24 V

After 30 minutes if the error is not rectified

V. Error

On

Flashes

On

0 V

0 V

Refer to table with flash codes

The short-circuit proof diagnostic output can be used for central

visualisation or control functions, e.g. in a PLC.

The electronic diagnostic output signals faults before the safety outputs

are disabled, thus enabling a controlled shutdown.

The diagnostic output is not a safety-relevant output!

The closed condition of the safety guard, i.e. the sensor is actuated,

is indicated through a positive signal. If the sensor is operating near

the limit of its switching distance, e.g. due to the sagging of the safety

guard, the sensor will emit a 1 Hz cyclic signal before the safety outputs

are disabled.

The diagnostic output can also be used to detect clearance variations

between the sensor and the actuator in the same way as the yellow

LED.

An active fault causes the diagnostic output to be disabled. The safety

outputs are disabled after max. 30 minutes if the fault is not rectified.

The signal combination, diagnostic output disabled and safety channels

still enabled, can be used to stop the production process in a controlled

manner.

Error

Any error that does not immediately affect the functionality of the safety

sensor (e.g. the ambient temperature being too high, interference

potential at a safety output, cross-wire short) will lead to a delayed

shut-down.

After fault rectification, the error message is reset by opening and re-

closing the corresponding safety guard. The safety outputs enable and

allow a restart.

Error warning

The safety outputs are disabled after 30 minutes if the error is not

rectified. The signal combination, diagnostic output disabled and

safety channels still enabled, can be used to stop the production

process in a controlled manner.