4

Operating instructions

Solenoid interlock

AZM 200

EN

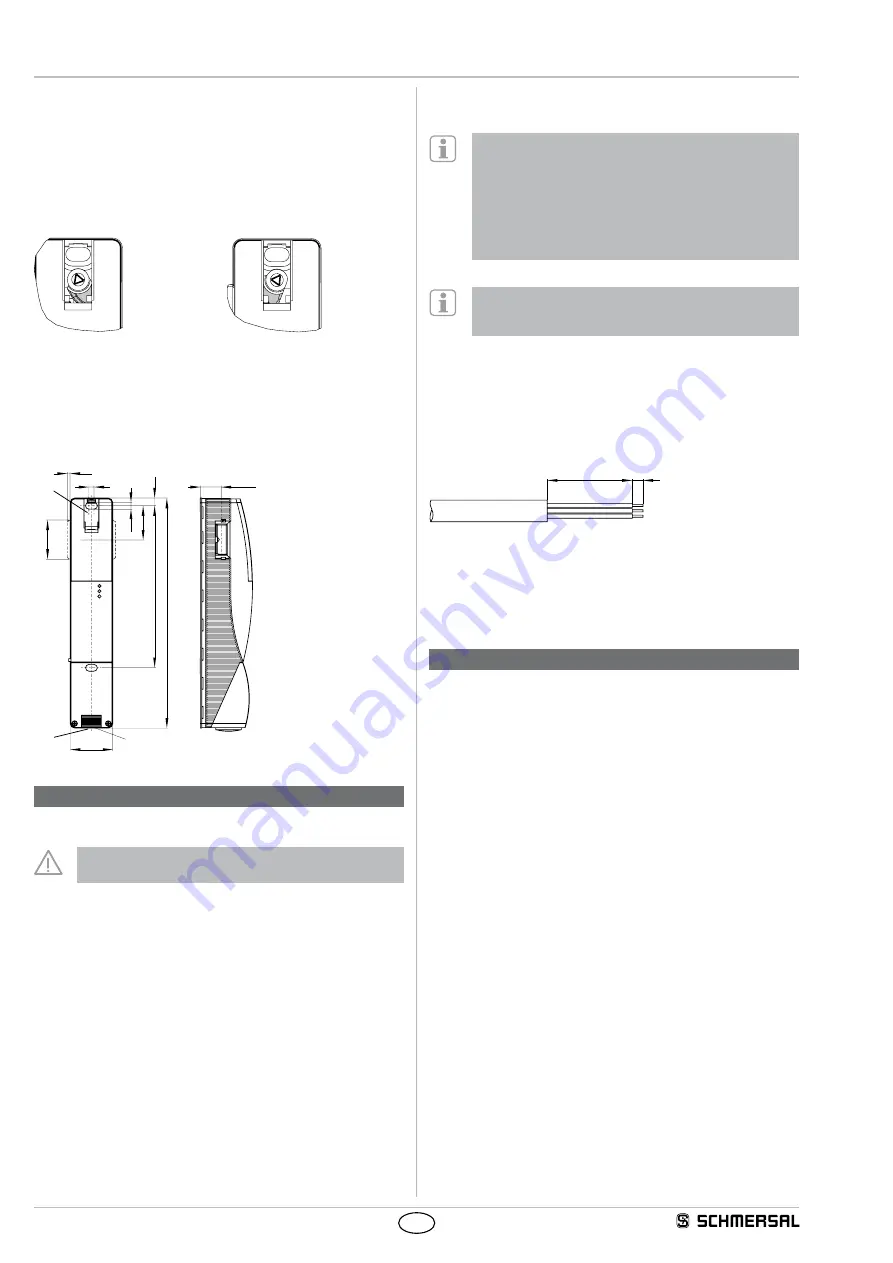

3.2 Manual release

For the machine set-up, the solenoid interlock can be unlocked in a

de-energised condition. After opening of the plastic flap "A" (refer to

image "Dimensions"), the triangular key must be turned clockwise

to bring the blocking bolt in unlocking condition. The normal locking

function is only restored after the triangular key has been returned to its

original position. Caution: do not turn beyond the latching point! After

being put into operation, the manual release must be secured by closing

the plastic flap "A" and affixing the seal, which is included in delivery.

Component ready

for operation

Component not ready

for operation

3.3 Dimensions

All measurements in mm.

40

220

155,5

5

6,5

32,5

38

7,5

M20x1,5

3,3

GN

RD

YE

20 1

±

A

B

Key

A: Manual release

B: Cable entry

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

The power supply for the solenoid interlock must provide protection

against permanent overvoltage. To that effect, stabilised PELV supply

units must be used. The safety outputs can be directly integrated in

the safety circuit of the control system. For applications up to PL e /

control category 4 to ISO 13849-1, the safety outputs of the solenoid

interlock(s) (max. 31 components (wired in series)) must be connected

to a safety-monitoring module of the same control category (refer to

wiring examples). Inductive loads (e.g. contactors, relays, etc.) are to

be provided with suitable interference suppression circuitry.

Requirements for the connected safety-monitoring module:

• Dual-channel safety input, suitable for 2 p-type semi-conductor outputs

Configuration of the safety controller

If the safety sensor is connected to electronic safety-

monitoring modules, we recommend that you set a

discrepancy time of 100 ms. The safety inputs of the safety-

monitoring module must be able to blank a test impulse of

approx. 1 ms. The safety-monitoring module does not need to

have a cross-wire short monitoring function, if necessary, the

cross-wire short monitoring function must be disabled.

Information for the selection of suitable safety-monitoring

modules can be found in the Schmersal catalogues or in the

online catalogue on the Internet: www.schmersal.net.

If the safety component is wired to relays or to non-safety relevant

control components, a new risk analysis must be carried out.

Cable

The cable entry is realised by a metric M20 gland. This gland must be

measured by the user so that it is suitable for the cable used. A cable

gland with strain relief and suitable IP protection class must be used.

40

5

The maximum cable length is 200 m (for ST2 M12 connectors approx.

20 m depending on the cable section used for an operating current

of 0.5 A). The maximum cable section is 1.5 mm², incl. conductuor

ferrules. Prior to the connection, the cable must be stripped by 40+5

mm and insulated by 5 mm. The fitted 24V, X1, X2 bridge is included in

the delivery of …-1P2P and …-SD2P.

5. Operating principle and diagnostic functions

5.1 Magnet control

In the power to unlock version of the AZM 200, the solenoid interlock

is unlocked when the IN signal (= 24V) is set. In the power to lock

version of the AZM 200, the solenoid interlock is locked when the IN

signal (= 24 V) is set.

5.2 Mode of operation of the safety outputs

In the standard AZM 200 variant, the unlocking of the solenoid interlock

causes the safety outputs to be disabled. The unlocked safety guard

can be relocked as long as the actuator is inserted in the AZM 200

solenoid interlock; in that case, the safety outputs are re-enabled.

The safety guard must not be opened.

In the B-variant AZM 200 B..., the opening of the safety guard causes

the safety outputs to be disabled.