Product Description

EN

· 30.30.01.02851 · 01 · 03/22

11 / 96

3

Product Description

3.1

Operating Principle of The Area Gripper

The area gripper is usually connected to a gantry or robot, which makes it possible to lift and move loads.

FXP-i Version

The integrated ejector generates the vacuum required for this purpose. The vacuum keeps the load attached to the

area gripper.

FMP-i Version

On the version for external vacuum generators, the vacuum, which is provided by a blower, is switched on and off as

required by the integrated valve.

3.2

Picking up the Load

FXP-i Version

The venturi nozzle on the ejector is activated and deactivated using the suction command:

•

In the NO (normally open) variant, the venturi nozzle is deactivated when the Suction signal is received.

•

In the NC (normally closed) variant, the venturi nozzle is activated when the suction signal is received.

An integrated sensor records the vacuum generated by the venturi nozzle. The exact vacuum level is shown on the

display and can be read from the IO-Link process data.

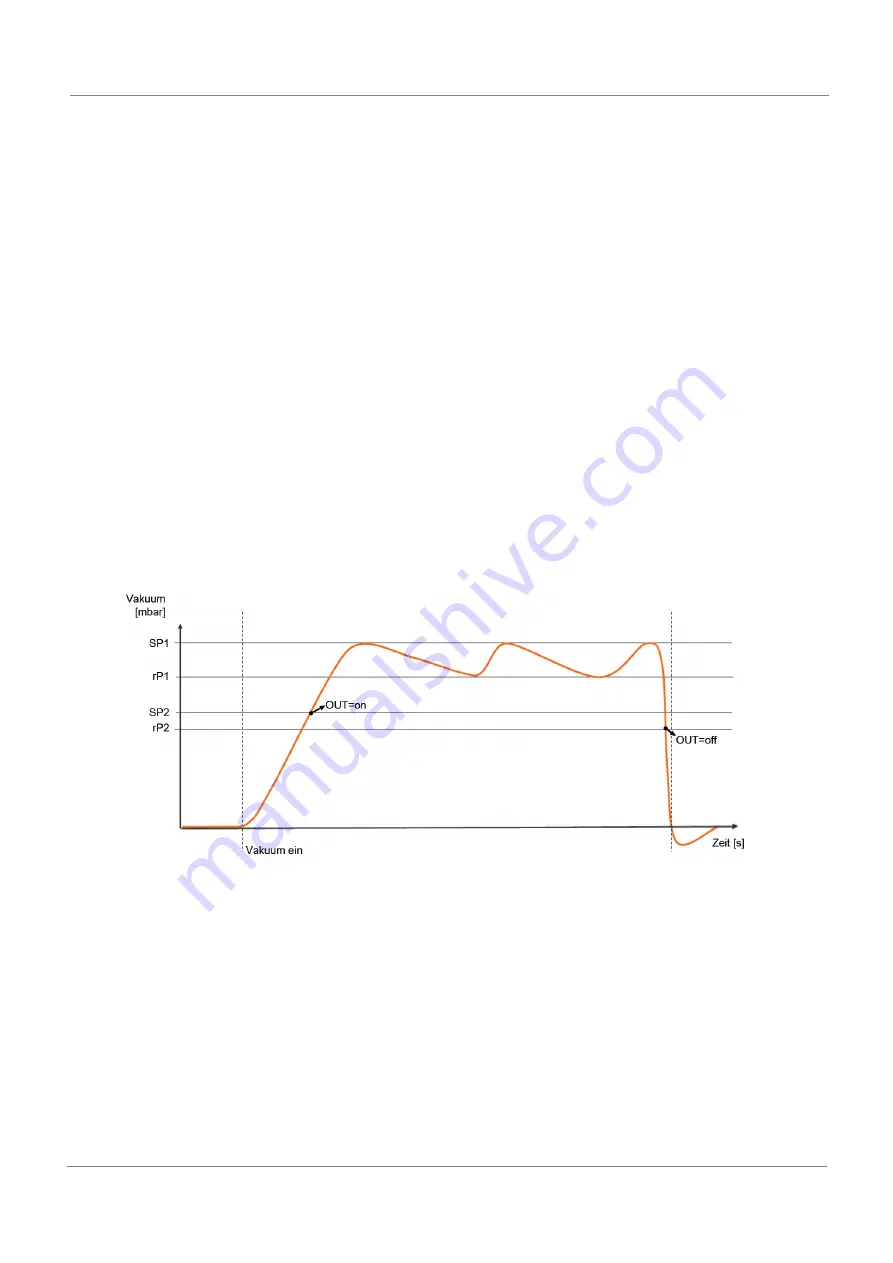

The diagram below shows the vacuum curve for when the air saving function is activated:

The integrated ejector has an air saving function and can control the vacuum automatically when the control function

is activated in suction mode:

•

The electronics switch the venturi nozzle off as soon as the vacuum limit value set for switching point SP1 is

reached.

•

When objects with airtight surfaces are picked up, the integrated non-return valve prevents the vacuum from

dropping.

•

If leakages cause the system vacuum to drop below the limit value configured for the switching point rP1, the

venturi nozzle is switched back on.

•

The OUT output is set once a workpiece is picked up securely, based on the vacuum value. This enables the

further handling process.