www.scheppach.com /

+(49)-08223-4002-99 /

+(49)-08223-4002-58

GB

| 33

•

Never set up or operate the equipment in the vicinity

of a fire place, open lights or sparking machines.

•

Do not store or eat food and drink in the work area.

Paint vapours are harmful to your health.

•

The work area must exceed 30 m³ and suffi cient

ventilation must be ensured during spraying and

drying.

•

Do not spray against the wind. Always adhere to

the regulations of the local police authority when

spraying combustible or hazardous materials.

•

Do not process media such as white spirit, butyl

alcohol and methylene chloride with the PVC

pressure hose. These media will destroy the

pressure hose.

•

The work area must be separated from the

compressor so that it cannot come into direct

contact with the working medium.

Operating pressure vessels

•

You must keep your pressure vessel in good work-

ing order, operate the vessel correctly, monitor the

vessel, carry out necessary maintenance and re-

pair work immediately and meet the relevant safety

precautions.

•

The supervisory authority may enforce essential

control measures in individual cases.

•

A pressure vessel is not allowed to be used if it has

faults or deficiencies that can endanger workers or

third parties.

•

Check the pressure vessel for signs of rust and

damage each time before using. Do not use the

compressor with a damaged or rusty pressure ves-

sel. If you discover any damage, then please con-

tact the customer service workshop.

Do not lose these safety instructions

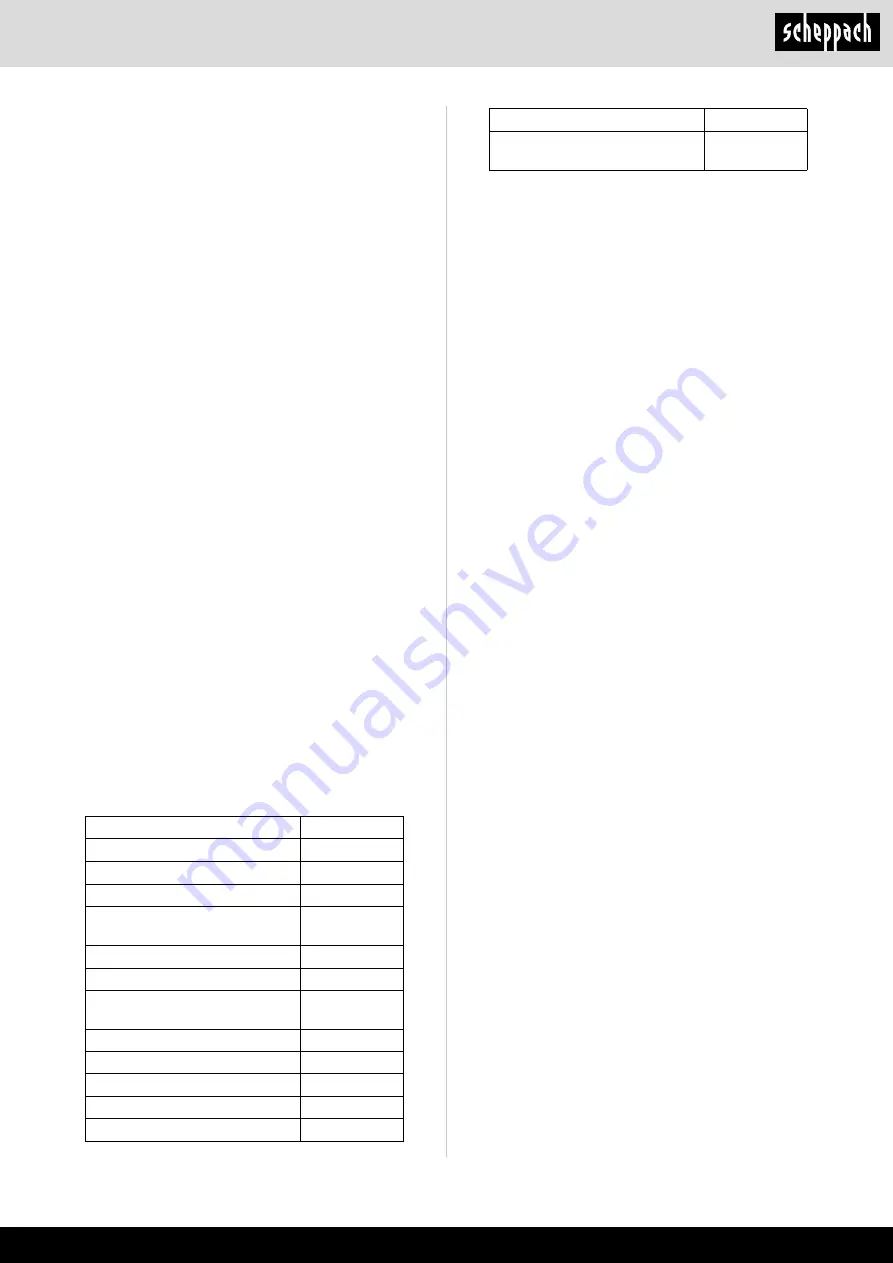

6. Technical data

Mains connection

230 V ~ 50 Hz

Motor rating W

2200

Operating mode

S1

Compressor speed

2850 min

-1

Pressure vessel capacity

(in liters)

50

Operating pressure

approx. 10 bar

Theoretical intake capacity (l/min)

approx. 412

Effective delivery quantity

approx

. 294 l/

min

Sound power level L

WA

93 dB(A)

Sound pressure level L

pA

71 dB(A)

Uncertainty K

WA

2.03 dB

Protection type

IP20

Weight of the unit in kg

approx. 41

Oil (15W 40) l

approx. 0,25

Max. altitude

(above mean sea level)

1000 m

The noise emission values were measured in accord-

ance with EN ISO 3744.

Wear hearing protection.

The effects of noise can cause a loss of hearing.

m

Avviso:

Il rumore può avere un grave impatto sulla

salute. Se il rumore della macchina è superiore a 85

dB (A), usare degli otoprotettori adeguati.

7. Before starting the equipment

•

Before you connect the equipment to the mains

supply make sure that the data on the rating plate

are identical to the mains data.

•

Prior to initial commissioning, remove the transport

plug and fill the crank housing with oil as described

in item 8.4.

•

Check the equipment for damage which may have

occurred in transit. Report any damage immedi-

ately to the transport company which was used to

deliver the compressor.

• Install the compressor near the point of consump

-

tion.

•

Avoid long air lines and supply lines (extension ca-

bles).

•

Make sure that the intake air is dry and dustfree.

•

Do not install the compressor in a damp or wet

room.

•

The compressor may only be used in suitable

rooms (with good ventilation and an ambient tem-

perature from +5 °C to 40 °C). There must be no

dust, acids, vapors, explosive gases or inflamma-

ble gases in the room.

•

The compressor is designed to be used in dry

rooms. It is prohibited to use the compressor in ar

-

eas where work is conducted with sprayed water.

• The oil level in the compressor pump has to be

checked before putting the equipment into opera-

tion.

•

The compressor may only be used outdoor briefly

when the ambient conditions are dry.

•

The compressor must always be kept dry and must

not be left outdoors after work is complete.