SY50U Excavator OMM

Maintenance

SANY

Operation and Maintenance Manual — 0120

5-61

TABLE OF

CONTENTS

INTRODUCTION

SAFETY

MACHINE

CONTROLS

MACHINE

OPERA

TION

MAINTENANCE

SPECIFICA

TIONS

OPTIONAL

EQUIPMENT

See “Lubrication and Maintenance Charts” on page

A new machine must be greased every 8 hours for the first 50 service hours.

If abnormal noise exists, additional lubrication is required.

More frequent lubrication is required when the machine is operated with heavy optional equipment

(e.g., a hydraulic breaker).

After operating in water, grease the machine to expel any water from the lubrication points.

1. Prepare the machine for service. See “Maintenance Safety” on page

2. Using a grease gun, pump grease into the grease fittings.

3. Clean off all excess grease.

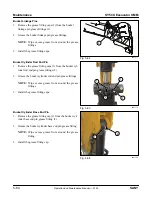

Arm Cylinder Rod End Pin

Fig. 5-54

0003171

1

2

1. Remove the grease fitting cap (1) from the arm cylin-

der rod end pin grease fitting (2).

2. Grease the arm cylinder rod end pin grease fitting.

NOTE:

Wipe excess grease from around the grease

fitting.

3. Install the grease fitting cap.

Boom-Arm Connecting Pin

Fig. 5-55

0003172

1

2

1. Remove the grease fitting cap (1) from the boom-arm

connecting pin grease fitting (2).

2. Grease the boom-arm connecting pin grease fitting.

NOTE:

Wipe excess grease from around the grease

fitting.

3. Install the grease fitting cap.

Содержание SY50U

Страница 2: ...This Page Intentionally Left Blank ...

Страница 212: ...Maintenance SY50U Excavator OMM 5 70 Operation and Maintenance Manual 0120 SANY This Page Intentionally Left Blank ...

Страница 220: ...Specifications SY50U Excavator OMM 6 8 Operation and Maintenance Manual 0120 SANY This Page Intentionally Left Blank ...

Страница 227: ...This Page Intentionally Left Blank ...