48

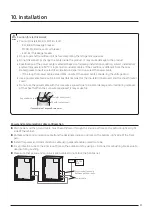

Refrigerant pipe installation

•

When installing, make sure there is no leakage. When collecting the refrigerant, stop the compressor first

before removing the connection pipe. If the refrigerant pipe is not properly connected and the compressor

is working with the service valve open, the pipe sucks the air in which makes the pressure inside of the

refrigerant cycle abnormally high which may lead to explosion and injury.

CAUTION

Refrigerant pipe work

▶

The length of refrigerant pipe should be as short as possible and the height difference between an indoor and

outdoor unit should be minimized.

▶

Piping work must be done within allowable piping length, height difference, and the allowable length after

branching.

▶

The pressure of the R-410A is high. Use only certified refrigerant pipe and follow the installation method.

▶

After installing the pipes, calculate the total length of the pipe to check if additional refrigerant is needed. When

you need to charge the additional refrigerant, make sure to use R-410A refrigerant.

▶

The inside of the refrigerant pipe must be clean and contain no harmful ions, oxides, dust, iron particles or

moisture.

▶

Use tools and accessories compatible with R-410A refrigerant gas.

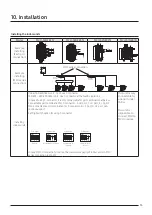

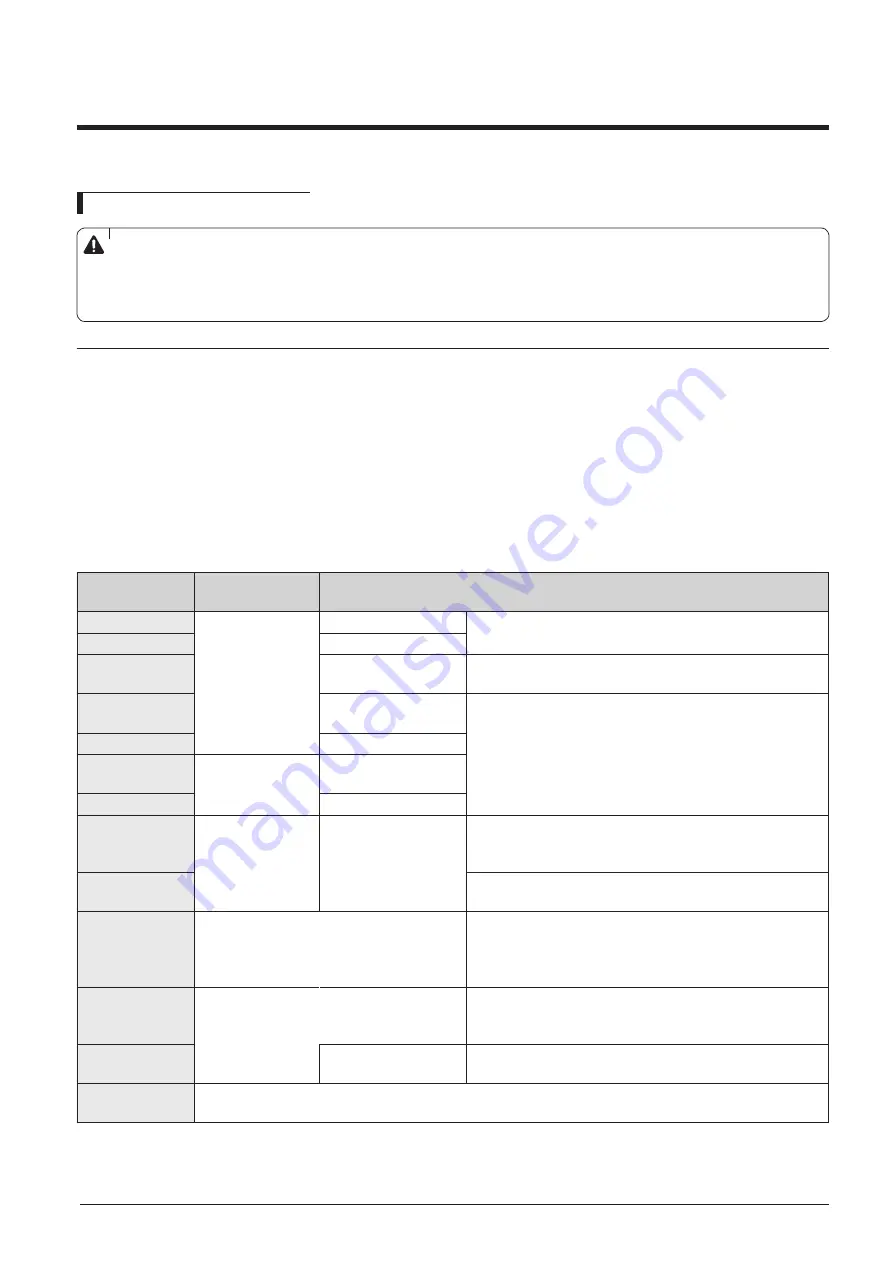

Tool

Installation

process/purpose

Compatibility with conventional tool

Pipe cutter

Refrigerant pipe

installation

Pipe cutting

Compatible

Flaring tool

Pipe flaring

Refrigerant

machine oil

Apply refrigerant oil

on flared part

Exclusive ether oil, ester oil, alkali benzene oil or

synthetic oil

Torque wrench

Connect flare nut

with pipe

Compatible

Pipe bender

Pipe bending

Nitrogen gas

Air tightness test

Prevent oxidation

within the pipe

Welder

Pipe welding

Manifold gage

Air tightness

test ~ additional

refrigerant

charging

Vacuuming, charging

refrigerant and

checking operation

Need exclusive one to prevent mixture of R-22

refrigerant oil use and also the measurement is not

available due to high pressure

Refrigerant

charging hose

Need exclusive one since there is risk of refrigerant

leakage or contamination

Vacuum pump

Pipe drying

Compatible (Use products which contain the check

valve to prevent the oil from flowing backward into

the outdoor unit.) Use the one that can be vacuumed

up to -100.7kpa(5Torr).

Scale for

refrigerant

charging

Compatible

Gas leak

detector

Gas leak test

Need exclusive one

(Ones used for R-134a is compatible)

Flare nut

Must use the flare nut supplied with the product. Refrigerant leakage may occur when the

conventional flare nut for R-22 is used.

10. Installation