- 31 -

YES

NO

NO

YES

YES

YES

NO

NO

NO

YES

NO

YES

YES

NO

NO

NO

YES

YES

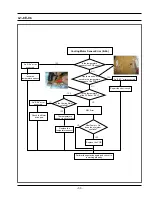

Over Time Error (S-01)

Perform the operation again and check if it

is working properly.

Re-check the Cut-Off-Time

for the corresponding

internal temperature.

Re-check the Cut-Off-Time

for the corresponding

internal temperature.

Re-check the Cut-Off-Time

for the corresponding

internal temperature.

Is it temperature

100°C in oven?

Is it temperature

105°C~240°C in oven?

Is it temperature

245°C in oven?

Does same error arise?

S/W Error

S/W Error

Does same error arise?

Does same error arise?

Has it worked for

8 hours continuously?

Has it worked for

6 hours continuously?

Has it worked for

4 hours continuously?

Turn the oven off and

let it cool sufficiently.

After Power > On,

does the symptom continue?

After Power > On,

does the symptom continue?

Replace the PCB.

Replace the PCB.

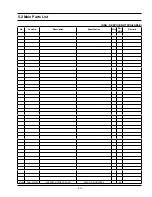

4-1-6 S-01

Содержание BQ1AD4T013/XEF

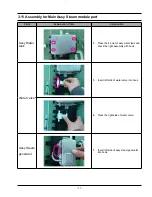

Страница 13: ... 11 3 8 Replacement of Assy Control Box Continued Remove 2 screws Remove 11 screws Remove 4 screws ...

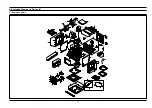

Страница 46: ... 44 5 2 Main Parts List No Code No Description Specification Q ty SA SNA Remark ...

Страница 51: ... 49 7 Wiring Diagram This Document can not be used without Samsung s authorization 7 1 Wiring Diagram ...