EB 2723 EN

29

Servicing

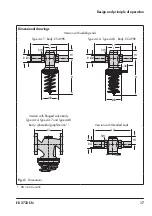

7.4 Tightening torques and lubricant

Î

Component

Valve size

Tightening torque in Nm

Stopper (1.1)

DN 15 to 25

70

DN 32 to 50

110

Seat (2)

DN 15 to 25

45

DN 32 to 50

110

Plug nut (3.2)

DN 15 to 25

4

DN 32 to 50

8

Plug nipple (3.5)

DN 32 to 50

110

Guide nipple (3.6)

DN 15 to 25

70

Coupling nut (4)

DN 15

200

DN 20

250

DN 25

300

DN 32

400

DN 40

600

DN 50

800

Control line connection (11)

DN 15 to 50

22

Body screws (13)

DN 15 to 32

8

DN 40 to 50

18

Diaphragm plate nut (15)

DN 15 to 25

40

DN 32 to 50

80

Lubricants

Item no.

Gleitmo 591

8150-0111

Change the nameplate and configuration ID

after changing the set point range.

Note

Содержание 44-4

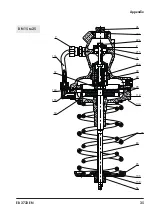

Страница 37: ...EB 2723 EN 37 Appendix 10 3 Certificates The EU declarations of conformity are in cluded on the next pages...

Страница 42: ...42 EB 2723 EN...

Страница 43: ...EB 2723 EN 43...